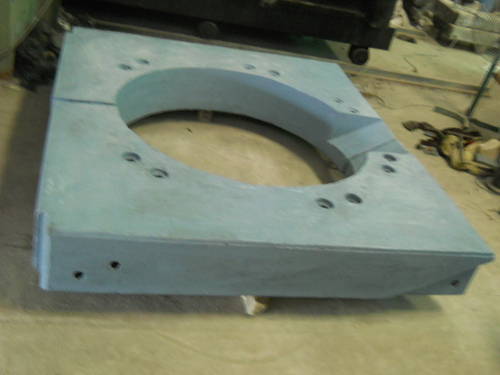

Refractory Top Cast

Refractory Top Cast Specification

- Cover

- No

- Medium

- Solid / Molten

- Connection Type

- Refractory Cast-in

- Hardness

- High

- Shape

- Rectangular / Custom

- Reinforcement

- Steel Fiber Reinforced

- Material

- High Alumina Refractory

- Temperature

- Up to 1750C

- Pressure

- Atmospheric

- Inside Diameter

- Customizable

- Outside Diameter

- Customizable

- Shelf Life

- 12 Months (Dry Condition)

- Density

- 2200-2400 kg/m³

- Resistance

- Excellent Thermal Shock & Slag Resistance

- Water Absorption

- <1%

- Color

- Light Grey / White

- Application

- Steel Plants, Furnaces, Boilers

- Installation Method

- Casting / Gunning

- Compressive Strength

- 70-80 MPa

- Thermal Conductivity

- Low

Refractory Top Cast Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Refractory Top Cast

With an objective to provide utmost satisfaction to our clients, we have been engrossed in manufacturing and supplying quality tested Refractory Top Cast. Provided product is manufactured using high grade raw material by our skilled professionals with latest innovative techniques at advanced production unit. This product is available in numerous specifications as per clients demand. Offered product is mainly used for holding induction coil tightly in middle of tilting furnace box. This product is highly admired among clients due to its robustness and excellent strength. Moreover, provided Refractory Top Cast is safely packed to avoid damage during transit.

High Performance for Extreme Conditions

Engineered for steel plants, furnaces, and boilers, the Refractory Top Cast delivers robust protection and insulation at high temperatures up to 1750C. Its high alumina content coupled with steel fiber reinforcement ensures durability under thermal and mechanical stress, enhancing service life and operational reliability.

Versatile Installation and Customization

This refractory material supports both casting and gunning installation methods, allowing seamless adaptation to various project needs. Dimensions such as inside and outside diameters can be customized, as can the shape, making it suitable for a wide range of industrial applications.

Excellent Resistance and Longevity

Thanks to its superior thermal shock and slag resistance, the Refractory Top Cast maintains performance even under rapid temperature changes and exposure to molten or solid mediums. Its low water absorption and robust build contribute to a shelf life of up to 12 months when stored in dry conditions.

FAQ's of Refractory Top Cast:

Q: How is the Refractory Top Cast installed?

A: The Refractory Top Cast can be installed using either the casting or gunning method, offering flexibility based on the specific needs and configurations of your project. Both techniques ensure proper adhesion and integration with existing refractory structures.Q: What applications is this refractory material best suited for?

A: This product is ideal for use in steel plants, furnaces, and industrial boilers where high durability and thermal resistance are required. Its customizable dimensions and resistance to thermal shock make it suitable for lining, repair, and maintenance jobs in high-temperature environments.Q: When should the Refractory Top Cast be replaced or maintained?

A: Replacement or maintenance schedules depend on operating conditions, but the material's high compressive strength and thermal shock resistance generally ensure an extended service life. Regular inspections are advised, especially in areas exposed to the most intense heat or mechanical stress.Q: Where is this refractory produced and supplied from?

A: This high alumina Refractory Top Cast is manufactured, exported, and supplied from India, serving clients globally, particularly in industries requiring customized and robust refractory solutions.Q: What is the process for customizing the dimensions of the Refractory Top Cast?

A: To customize inside or outside diameters or overall shape, you may specify dimensional requirements during your order. Our manufacturing team will tailor the product to meet your precise application needs, ensuring optimal fit and performance.Q: What benefits does the steel fiber reinforcement provide?

A: Steel fiber reinforcement enhances the structural integrity and mechanical strength of the refractory at both ambient and high temperatures. It significantly improves resistance to cracking and spalling under thermal cycling, prolonging the refractory's operational lifespan.Q: How does low thermal conductivity benefit industrial operations?

A: Low thermal conductivity minimizes heat loss, improving energy efficiency and lowering operational costs in high-temperature settings. It also contributes to safer working environments by keeping outer surfaces cooler.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Spare Parts Category

Refractory Castable Top Block

Minimum Order Quantity : 10 Pieces

Cover : Dense Castable Cover

Pressure : Atmospheric to Moderate

Medium : Other, Suitable for Solid, Liquid, Gas Environments

Outside Diameter : As per requirement / Custom sizes

Refractory Bottom Cast

Minimum Order Quantity : 10 Pieces

Cover : Not included

Pressure : Standard Atmospheric

Medium : Other, Molten Metal/Slag

Outside Diameter : 220 mm

Carbon Free Hose

Minimum Order Quantity : 10 Pieces

Cover : Special compound synthetic rubber, heat & electrical resistant (Green/Red/Blue/Black)

Pressure : 15 Bar (218 psi)

Medium : Other, Suitable for conveying water and nonconductive fluids

Outside Diameter : 22 mm to 65 mm

Refractory Castable Bottom

Minimum Order Quantity : 10 Pieces

Cover : Open / As required

Pressure : Atmospheric

Medium : Other, Suitable for molten metal, slag, and hot gases

Outside Diameter : Customizable as per requirement

Send Inquiry

Send Inquiry