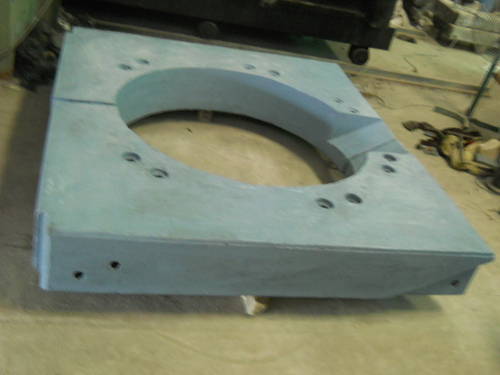

Refractory Castable Top Block

Refractory Castable Top Block Specification

- Hardness

- High

- Cover

- Dense Castable Cover

- Reinforcement

- Steel Fibers (optional)

- Medium

- Suitable for Solid, Liquid, Gas Environments

- Connection Type

- Mortar Joint / Cast-in-Place

- Shape

- Rectangular Block

- Material

- High Alumina Refractory Castable

- Temperature

- Up to 1600C

- Pressure

- Atmospheric to Moderate

- Inside Diameter

- As per requirement / Custom sizes

- Outside Diameter

- As per requirement / Custom sizes

- Water Absorption

- 5%

- Density

- 2200 - 2600 kg/m

- Thermal Conductivity

- Low, excellent insulation properties

- Application

- Roof blocks for furnaces, kilns, boilers

- Compliance

- IS 10570 / Equivalent international standards

- Packaging

- As per standard export packaging

- Cold Crushing Strength

- 50 MPa

- Color

- Light Grey

- Service Life

- Up to 5 Years

- Features

- Thermal shock resistance, abrasion resistance, corrosion resistance

- Installation

- Vibration Casting / Pouring

Refractory Castable Top Block Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Refractory Castable Top Block

Having an enormous experience and profound knowledge & expertise in the industry, we are a renowned manufacturer and supplier of Refractory Castable Top Block. These blocks are used in industrial furnaces as blankets for insulation. To comply with the set industrial norms, we use finest quality materials to manufacture the blocks. Our quality inspectors check the Refractory Castable Top Block on durability and finishing parameters to offer a flawless range to the clients.

Features:

-

Rugged design

-

Crack free finishing

-

Easy to assemble

Reliable Insulation for High-Temperature Applications

Engineered to provide low thermal conductivity and exemplary insulation, these refractory castable top blocks are ideal for furnace, kiln, and boiler roofs. Their resilience against extreme temperatures-up to 1600C-guarantees thermal stability, prolonging equipment lifespan and boosting safety.

Enhanced Mechanical Strength and Durability

With a cold crushing strength of at least 50 MPa, these blocks resist abrasion, corrosion, and thermal shock, making them suitable for heavy-duty operations. The high alumina formulation paired with optional steel fiber reinforcement further enhances longevity and structural integrity.

Versatile Installation and Custom Sizing

Available in rectangular shapes with specified inside and outside diameters, the blocks can be installed using vibration casting or pouring. The mortar joint or cast-in-place connections provide adaptability for different project requirements, catering to various solid, liquid, or gas processing environments.

FAQ's of Refractory Castable Top Block:

Q: How is the Refractory Castable Top Block installed in roof applications?

A: Installation is performed via vibration casting or pouring, ensuring an even and secure fit. Mortar joints or cast-in-place methods can be selected based on project specifications, facilitating flexibility during assembly.Q: What are the main benefits of using this block as a roof material in furnaces and kilns?

A: The key benefits include low thermal conductivity, high insulation, resistance to thermal shock, abrasion, and corrosion, all of which help maintain operational stability and extend the structure's service life to up to five years.Q: When should I select custom sizes for inside and outside diameters?

A: Custom sizes should be chosen when your furnace, kiln, or boiler design requires non-standard dimensions to ensure a proper fit and optimum sealing. This customization enhances thermal efficiency and structural performance.Q: Where can this refractory block be used beyond furnace roof applications?

A: Apart from furnace and kiln roofs, these blocks are suitable for boilers and any high-temperature environment requiring insulation and durability against solid, liquid, or gas mediums, thanks to their robust material and resistance features.Q: What process does the block undergo to meet international standards?

A: Each block is manufactured under strict quality controls to comply with IS 10570 and equivalent international standards, ensuring consistent density, strength, and low water absorption. Optional steel fiber reinforcement can be incorporated for added mechanical performance.Q: How does the block's low water absorption contribute to its performance?

A: With water absorption limited to 5%, the block offers improved durability and resistance to spalling and chemical attack. This feature helps maintain insulation properties and structural integrity over prolonged, high-temperature usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Spare Parts Category

Refractory Bottom Cast

Minimum Order Quantity : 10 Pieces

Medium : Other, Molten Metal/Slag

Outside Diameter : 220 mm

Shape : Cylindrical

Pressure : Standard Atmospheric

Refractory Top Cast

Minimum Order Quantity : 10 Pieces

Medium : Other, Solid / Molten

Outside Diameter : Customizable

Shape : Rectangular / Custom

Pressure : Atmospheric

Carbon Free Hose

Minimum Order Quantity : 10 Pieces

Medium : Other, Suitable for conveying water and nonconductive fluids

Outside Diameter : 22 mm to 65 mm

Shape : Round

Pressure : 15 Bar (218 psi)

Refractory Castable Bottom

Minimum Order Quantity : 10 Pieces

Medium : Other, Suitable for molten metal, slag, and hot gases

Outside Diameter : Customizable as per requirement

Shape : Rectangular / As per drawing

Pressure : Atmospheric

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free