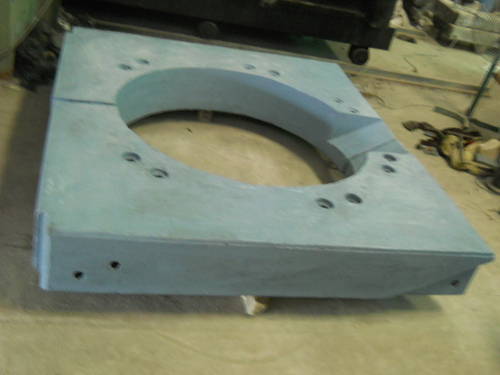

Refractory Bottom Cast

Refractory Bottom Cast Specification

- Hardness

- High

- Reinforcement

- Without Reinforcement

- Shape

- Cylindrical

- Connection Type

- Socket Joint

- Medium

- Molten Metal/Slag

- Cover

- Not included

- Material

- High Alumina Castable Refractory

- Temperature

- Up to 1600C

- Pressure

- Standard Atmospheric

- Inside Diameter

- 180 mm

- Outside Diameter

- 220 mm

- Finish

- Smooth

- Color

- Grey

- Cold Crushing Strength

- > 60 MPa

- Installation

- Monolithic Cast-in-situ

- Usage

- Furnace Bottom & Industrial Kilns

- Density

- 2.3-2.5 g/cm³

- Thermal Conductivity

- Low

- Service Life

- > 2 Years

Refractory Bottom Cast Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Refractory Bottom Cast

Since 2010, we have been engrossed in manufacturing and supplying a wide range of Refractory Bottom Cast. Offered product is ideal for holding induction coil tightly in middle of tilting furnace box. Provided product is manufactured using quality approved components by our dexterous professionals at well-equipped production unit. This product is available in numerous specifications according to need of clients. Provided product is tested on various quality parameters to ensure its durability. Offered product is highly appreciated among clients due to its excellent functionality. In addition, this Refractory Bottom Cast can be purchased from us at industrial leading prices.

High Performance for Demanding Applications

This refractory bottom cast is designed to withstand harsh industrial environments, offering high hardness, excellent resistance against molten metals and slag, and a service life exceeding two years under temperatures as high as 1600C. Its high-alumina composition ensures long-lasting strength while maintaining low thermal conductivity to enhance energy efficiency.

Precision Engineering for Seamless Installation

With a monolithic cast-in-situ installation, the cylindrical cast with a socket joint connection provides a precise and secure setup, avoiding joint weaknesses. Its smooth finish ensures optimal fit and minimizes material buildup, making it ideal for both new construction and repairs in furnaces and kilns.

FAQ's of Refractory Bottom Cast:

Q: How is the Refractory Bottom Cast installed in industrial furnaces?

A: The Refractory Bottom Cast is designed for monolithic cast-in-situ installation, meaning it is poured and cast directly at the site. This approach provides a seamless, joint-free structure, significantly enhancing durability and resistance to harsh operating conditions.Q: What are the primary benefits of using a high-alumina castable refractory bottom?

A: High-alumina castable refractories offer superior strength, high temperature resistance up to 1600C, low thermal conductivity, and excellent chemical stability against molten metal and slag, ensuring extended service life and efficient operation in demanding furnace and kiln environments.Q: When should I consider replacing the refractory bottom cast?

A: Replacement is generally recommended after the product has served beyond its expected service life of over two years, or if you notice significant wear, reduced performance, or visible damage. Regular inspection helps ensure timely maintenance and continued safe operation.Q: Where is this refractory bottom cast typically used?

A: This product is commonly used in the bottom sections of industrial kilns and furnaces, particularly in sectors dealing with molten metals or slag, such as steel, glass, and ceramics industries.Q: What is the process for casting this refractory bottom on site?

A: The process involves preparing the casting area, mixing the high-alumina refractory material with water as specified, and pouring it into the designated mold or location inside the furnace. After placement, it is cured and dried according to recommended procedures to achieve optimal strength and durability.Q: What advantages does the socket joint connection offer?

A: The socket joint connection ensures a secure mechanical fit, simplifies alignment during installation, and enhances the integrity of the cylindrical structure, reducing the risk of leaks or structural weaknesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Spare Parts Category

Carbon Free Hose

Minimum Order Quantity : 10 Pieces

Temperature : 40C to +100C

Hardness : 70 5 Shore A

Reinforcement : High tensile synthetic textile ply

Outside Diameter : 22 mm to 65 mm

Refractory Top Cast

Minimum Order Quantity : 10 Pieces

Temperature : Up to 1750C

Hardness : High

Reinforcement : Steel Fiber Reinforced

Outside Diameter : Customizable

Refractory Castable Bottom

Minimum Order Quantity : 10 Pieces

Temperature : Up to 1500C

Hardness : >60 Shore D

Reinforcement : Steel fiber reinforced

Outside Diameter : Customizable as per requirement

Refractory Castable Top Block

Minimum Order Quantity : 10 Pieces

Temperature : Up to 1600C

Hardness : High

Reinforcement : Steel Fibers (optional)

Outside Diameter : As per requirement / Custom sizes

Send Inquiry

Send Inquiry