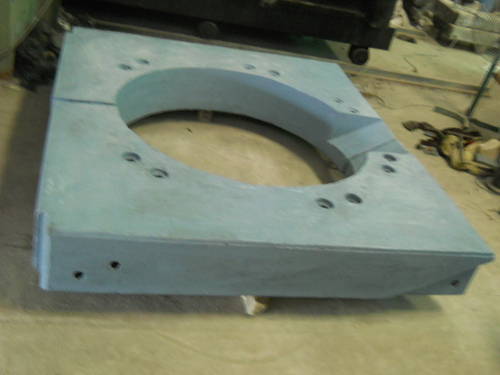

Refractory Castable Bottom

Refractory Castable Bottom Specification

- Cover

- Open / As required

- Connection Type

- Monolithic pour / Cast-in-place

- Hardness

- >60 Shore D

- Shape

- Rectangular / As per drawing

- Reinforcement

- Steel fiber reinforced

- Medium

- Suitable for molten metal, slag, and hot gases

- Material

- High-alumina refractory castable

- Temperature

- Up to 1500C

- Pressure

- Atmospheric

- Inside Diameter

- Customizable as per requirement

- Outside Diameter

- Customizable as per requirement

- Color

- Light Grey

- Cold Crushing Strength

- >60 MPa (After firing)

- Compressive Strength after 24hr Air Cure

- >30 MPa

- Porosity

- Low, <18%

- Max Service Temperature

- 1500°C

- Application Area

- Furnace bottom, ladle lining, kiln bottom

- Packaging Type

- HDPE Bags or Customized

- Installation Method

- Castable / Pouring

- Shelf Life

- 12 Months

- Water Requirement for Mixing

- 8-10% by weight

- Setting Time

- Initial: 3-5 Hours

- Bulk Density

- 2.3-2.6 g/cm³

- Resistance

- High abrasion and spalling resistance

- Thermal Conductivity

- Low, enhances thermal efficiency

Refractory Castable Bottom Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Refractory Castable Bottom

As a leading organizations in this domain, we have been engrossed in manufacturing and supplying high grade Refractory Castable Bottom. This item is used for making monolithic lining and refractory products. Offered item is known for its accurate dimension, longer life, high strength, optimum thickness and user-friendly design. This item is highly admired among clients owing to its unique design and easy installation. Provided item is tested on various parameters to ensure its flawless delivery to clients. Offered item is manufactured using quality assured raw material under supervision of our experienced professionals. In addition, this Refractory Castable Bottom is safely packed to avoid damage during transit.

Superior Performance in High-Temperature Environments

Designed for harsh thermal conditions, this refractory castable offers excellent stability and strength at temperatures up to 1500C. Its high abrasion resistance and low porosity ensure dependable operation in environments exposed to molten metals, slags, and hot gases, minimizing downtime and maintenance costs.

Efficient and Flexible Installation Process

Installation is straightforward, as the product can be cast or poured directly onsite, adapting to rectangular or custom shapes and diameters. A 8-10% water addition by weight ensures optimal workability, with an initial set time of 3-5 hours, allowing for quick and efficient project turnaround.

Comprehensive Customization and Protection

Available in HDPE bags or customized packaging, this castable bottom is reinforced with steel fibers and can be configured to fit various equipment sizes based on specific requirements. Its long shelf life and customizable design provide flexibility, making it suitable for a wide range of industrial applications.

FAQ's of Refractory Castable Bottom:

Q: How should the Refractory Castable Bottom be prepared and installed?

A: Mix the castable with 8-10% water by weight until a homogenous consistency is achieved. Install by casting or pouring into the desired shape or formwork. Ensure proper compaction for maximum strength, and allow an initial set time of 3-5 hours for optimal results.Q: What are the main benefits of using this refractory castable bottom?

A: This product provides high cold crushing and compressive strength, excellent thermal efficiency due to its low thermal conductivity and porosity, and superior resistance to abrasion and spalling. These advantages extend the service life of the furnace bottom and reduce maintenance frequency and costs.Q: When is the Refractory Castable Bottom fully serviceable after application?

A: After pouring or casting, initial strength develops within 3-5 hours; however, full compressive strength is typically achieved after a 24-hour air cure, attaining values above 30 MPa. Post-firing, the cold crushing strength exceeds 60 MPa, making it ready for standard operations.Q: Where can this refractory castable be applied most effectively?

A: It is ideally suited for furnace bottoms, ladle linings, and kiln bottoms in metallurgical, foundry, and cement industries. Its robust performance makes it compatible with environments dealing with molten metal, slag, and hot gases.Q: What is the shelf life and storage requirement for this castable material?

A: The castable is supplied in moisture-protective HDPE bags or custom packaging, with a shelf life of up to 12 months if stored in dry, covered conditions away from moisture and direct sunlight.Q: How does the product improve thermal efficiency in industrial operations?

A: With low thermal conductivity and minimal porosity (<18%), the castable reduces heat loss, promoting better energy retention within furnaces and kilns, thereby improving overall process efficiency and lowering operational energy costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Spare Parts Category

Refractory Top Cast

Minimum Order Quantity : 10 Pieces

Hardness : High

Temperature : Up to 1750C

Inside Diameter : Customizable

Medium : Other, Solid / Molten

Refractory Bottom Cast

Minimum Order Quantity : 10 Pieces

Hardness : High

Temperature : Up to 1600C

Inside Diameter : 180 mm

Medium : Other, Molten Metal/Slag

Carbon Free Hose

Minimum Order Quantity : 10 Pieces

Hardness : 70 5 Shore A

Temperature : 40C to +100C

Inside Diameter : 12 mm to 50 mm

Medium : Other, Suitable for conveying water and nonconductive fluids

Refractory Castable Top Block

Minimum Order Quantity : 10 Pieces

Hardness : High

Temperature : Up to 1600C

Inside Diameter : As per requirement / Custom sizes

Medium : Other, Suitable for Solid, Liquid, Gas Environments

Send Inquiry

Send Inquiry