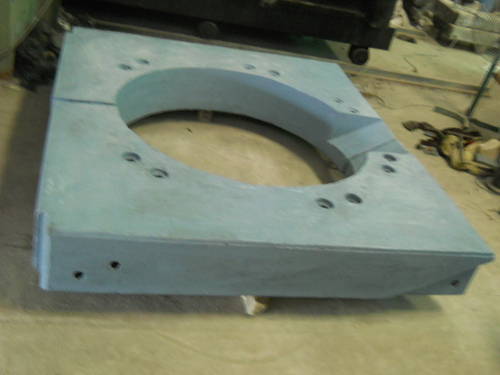

Refractory Castable Top

Refractory Castable Top Specification

- Hardness

- 75-85 HRB

- Cover

- Fire Resistant Coating

- Medium

- High Temperature Applications

- Reinforcement

- Optional Steel Fibers

- Shape

- Round/Rectangular/Custom

- Material

- Alumina, Silica, High-Grade Binders

- Temperature

- Up to 1800C

- Pressure

- Atmospheric

- Inside Diameter

- Varies as per requirement

- Outside Diameter

- Varies as per requirement

- Corrosion Resistance

- High

- Water Addition

- 6-8% by weight

- Color

- Light Grey to Off White

- Compressive Strength

- High, suitable for industrial use

- Setting Time

- Initial: 4-6 hours, Final: 24 hours

- Packaging Type

- HDPE Bags or Sacks

- Chemical Resistance

- Excellent against slag and molten metal

- Installation Method

- Vibration Casting or Pouring

- Thermal Conductivity

- Low, Provides Good Insulation

- Cold Crushing Strength

- Minimum 60 MPa

- Shelf Life

- 6 Months from Manufacturing

- Application Areas

- Furnaces, Kilns, Boiler Linings, Incinerators

- Bulk Density

- 2.2 2.6 g/cm

Refractory Castable Top Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Refractory Castable Top

We are a prominent firms in this domain, engrossed in manufacturing and supplying quality approved Refractory Castable Top. this item is manufactured using fine grade raw material under observation of our skilled professionals with latest innovative techniques. This top is an essential refractory part that is used for ensuring smooth functionality of refractory system. Offered top is highly admired among clients owing to its unique design, user-friendly in nature, robustness, enhanced durability and free from defect. Provided item is safely packed for preventing damage during transit. In addition to this, offered Refractory Castable Top can be purchased from us in different specifications according to requirements of clients at industrial leading prices.

Superior Strength and Chemical Resistance

Engineered with high-grade alumina, silica, and premium binders, this refractory castable ensures exceptional mechanical integrity under intense loads. It stands up effectively to aggressive chemical agents found in slag and molten metals, making it ideal for critical industrial applications where durability and chemical resistance are paramount.

Reliable Insulation and Versatile Applications

With its low thermal conductivity, the castable offers reliable heat insulation, contributing to enhanced energy efficiency in furnaces, kilns, and boilers. Its adaptability to round, rectangular, or custom shapes, along with easy installation by vibration casting or pouring, makes it a versatile solution across various high-temperature industrial processes.

Convenient Packaging and Longevity

Packaged in robust HDPE bags or sacks, the product ensures safety and ease of transport. It maintains a shelf life of six months from the manufacturing date when stored properly, offering flexibility for inventory management and planned maintenance schedules.

FAQ's of Refractory Castable Top:

Q: How is Refractory Castable Top installed for industrial use?

A: Refractory Castable Top is primarily installed using vibration casting or pouring methods. The material is mixed with 6-8% water by weight, poured or cast into the desired cavity, and then compacted to remove air pockets. Steel fiber reinforcement can be added if required, depending on the application's mechanical load demands.Q: What makes this refractory castable suitable for high-temperature environments?

A: Its composition of high-grade alumina, silica, and advanced binders provides a cold crushing strength of at least 60 MPa and a high resistance to thermal shock, corrosion, and abrasion. The product can withstand temperatures up to 1800C, making it ideal for environments such as furnaces, kilns, and incinerators.Q: When should the castable be used after mixing with water?

A: Once mixed with the recommended amount of water, the castable should be installed promptly. The initial setting time is between 4 to 6 hours, and the final setting occurs within 24 hours, ensuring a timely project turnover without compromising structural integrity.Q: Where is this refractory castable commonly applied?

A: This product is widely used in high-temperature zones of furnaces, kilns, boiler linings, and incinerators. Its excellent chemical and thermal properties make it suitable for both new installations and repair work in heavy industrial settings.Q: What is the benefit of the product's excellent chemical resistance?

A: The castable's outstanding resistance to slag and molten metal extends the lifespan of thermal linings in harsh operating environments. This minimizes downtime due to maintenance or premature failure, optimizing facility productivity and operational efficiency.Q: How does its packaging and shelf life support industrial operations?

A: Supplied in HDPE bags or sacks, the refractory castable is protected from moisture and contamination, ensuring quality upon delivery. It boasts a shelf life of six months, providing flexibility for storage and allowing users to schedule projects efficiently.Q: Can the shape and reinforcement of the castable be customized as per project requirements?

A: Yes, the refractory castable is available in standard round, rectangular, or custom shapes to meet diverse project demands. Optional steel fiber reinforcement can also be included to boost mechanical toughness when necessary.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Spare Parts Category

Refractory Castable Bottom

Minimum Order Quantity : 10 Pieces

Medium : Other, Suitable for molten metal, slag, and hot gases

Temperature : Up to 1500C

Cover : Open / As required

Hardness : >60 Shore D

Carbon Free Hose

Minimum Order Quantity : 10 Pieces

Medium : Other, Suitable for conveying water and nonconductive fluids

Temperature : 40C to +100C

Cover : Special compound synthetic rubber, heat & electrical resistant (Green/Red/Blue/Black)

Hardness : 70 5 Shore A

Refractory Bottom Cast

Minimum Order Quantity : 10 Pieces

Medium : Other, Molten Metal/Slag

Temperature : Up to 1600C

Cover : Not included

Hardness : High

Refractory Top Cast

Minimum Order Quantity : 10 Pieces

Medium : Other, Solid / Molten

Temperature : Up to 1750C

Cover : No

Hardness : High

Send Inquiry

Send Inquiry