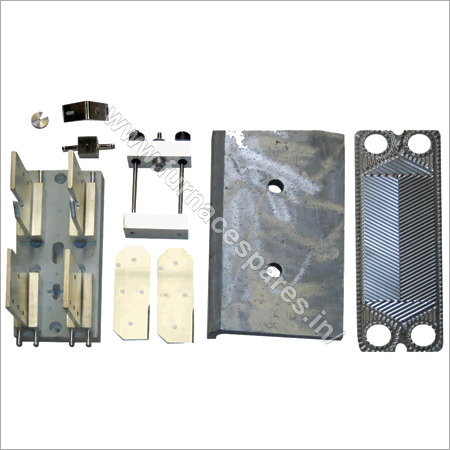

Induction Furnace Assembly Parts

Induction Furnace Assembly Parts Specification

- Feature

- High Strength, Precision Machined, Heat Resistant, Rust Proof

- Rating

- Up to 5000 kW (depends on part type)

- Condition

- New

- Type

- Furnace Assembly Parts

- Usage

- Industrial Melting and Heating

- Power

- Dependant on Key Part (Coil, busbar etc.)

- Voltage

- 380-415V (Customizable)

- Size

- Customizable as per furnace design

- Dimensions

- As per customer specification or drawing

- Weight

- Varies as per part; ranges from 0.5 kg to 150 kg

- Application

- Induction Furnaces Melting, Holding, Heating Metals

- Fuel Type

- Electric

- Capacity

- Compatible with 100 kg-15 ton induction furnaces

- Manufacturing Process

- Precision Machining, Fabrication, Plasma Cutting, Casting

- Packaging

- Durable Corrugated Box/Wooden Crate/Shrink-wrapped for safety

- Part Examples

- Induction Coil, Yoke, Bus Bar, Terminal Plate, Clamp, Gasket, Support Stand, Insulator

- Insulation Class

- H-Class or as specified

- Material

- Copper, Stainless Steel, Mild Steel, Brass, FRP, Ceramic, Asbestos Free Gasket

- Compatibility

- Supports both Coreless and Channel Type Induction Furnaces

- Surface Finish

- Polished/Coated/Plated for enhanced durability

- Mounting Type

- Bolt/Clamp/Slot/Custom

- Color

- Metallic/Custom Painted as per requirement

- Temperature Resistance

- Up to 1500°C (part dependent)

- Lead Time

- 2-5 weeks (depending on order volume and part complexity)

Induction Furnace Assembly Parts Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Induction Furnace Assembly Parts

Being a trusted firm in this domain, we have been engaged in manufacturing and supplying quality approved Induction Furnace Assembly Parts. Offered parts are mainly used to assemble induction furnace in manufacturing industries. provided parts is available in various specifications according to requirements of clients. These parts are known for their accurate dimension, optimum strength, robustness, corrosion resistant body and longer life. Easy to install and assemble, offered parts are highly admired among clients. These parts are manufactured using quality approved components by our adept professionals. In addition, provided Induction Furnace Assembly Parts are safely packed to avoid damage during transit.

Engineered for High-Temperature Applications

Our assembly parts withstand intensive industrial environments, offering reliable operation at temperatures up to 1500C, as part-dependent. Crafted from heat-resistant and rust-proof materials, these components ensure optimal safety and performance in melting, holding, and heating metals.

Flexible Compatibility and Customization

Supporting both coreless and channel induction furnaces, our parts can be tailored to your specific furnace designs. Options include different mounting styles, surface finishes, and custom colors. We match your exact requirements, ensuring seamless integration with your existing systems.

Precision Manufacturing for Lasting Durability

Utilizing advanced manufacturing techniques like precision machining, plasma cutting, and fabrication, we deliver parts with exceptional dimensional accuracy and high structural integrity. Each product undergoes strict quality checks to guarantee reliability in demanding industrial conditions.

FAQ's of Induction Furnace Assembly Parts:

Q: How do your induction furnace assembly parts support both coreless and channel type furnaces?

A: Our parts are engineered with adaptable mounting options and customizable dimensions, making them fully compatible with both coreless and channel type induction furnaces. This ensures seamless fitment and optimal functionality, regardless of furnace design.Q: What manufacturing processes are utilized for these assembly parts?

A: We use precision machining, fabrication, plasma cutting, and casting to manufacture our furnace assembly parts. These processes enable us to achieve high structural accuracy, superior surface finishes, and reliable performance in high-temperature applications.Q: When can I expect delivery after placing an order?

A: Lead times typically range from 2 to 5 weeks, depending on the order volume and the complexity of the requested parts. We prioritize timely deliveries while maintaining rigorous quality standards.Q: Where are these parts used and who are they suitable for?

A: Our assembly parts are primarily used in industrial induction furnaces for melting, holding, and heating metals. They are ideal for manufacturers, exporters, suppliers, and traders involved in metal processing and foundry operations.Q: What are the key benefits of your induction furnace assembly parts?

A: These parts offer high heat resistance, customizable design, robust durability, rust-proof surfaces, and compatibility with a wide range of furnace types and sizes. Their precise engineering ensures reliability and extended service life, reducing downtime and maintenance costs.Q: How are the parts packaged to ensure safe delivery?

A: We package our parts in durable corrugated boxes, wooden crates, or shrink-wrap-depending on size and fragility-to protect them during transit and safeguard product quality upon arrival.Q: What is the range of furnace capacities and ratings your parts can accommodate?

A: Our assembly parts are designed to support furnaces with capacities from 100 kg to 15 tons and can handle ratings up to 5000 kW, making them suitable for small-scale to large industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Furnace Assembly Category

Induction Furnace Parts

Minimum Order Quantity : 10 Pieces

Capacity : Varies by part

Size : Standard, As per furnace model

Weight : Depends on specific part

Type : Spare Parts

Induction Melting Furnace Assembly

Minimum Order Quantity : 10 Pieces

Capacity : 10 kg to 2000 kg

Size : Customizable as per requirement

Weight : Depends on model (starts at 200 kg)

Type : Induction Melting Furnace

Spare Part Induction Furnace

Minimum Order Quantity : 10 Pieces

Capacity : Depends on Part and Furnace Model

Size : Standard, Customizable

Weight : Varies by Part

Type : Induction Furnace Spare Part

Induction Furnace Coil

Minimum Order Quantity : 10 Pieces

Capacity : Upto 5 Tons

Size : Customizable as per requirement

Weight : Depending on design and capacity

Type : Induction Furnace Coil

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free