Induction Melting Furnace Assembly

Induction Melting Furnace Assembly Specification

- Feature

- Low energy consumption, Fast melting, Ergonomic design, Precise temperature control

- Rating

- High Efficiency

- Condition

- New

- Type

- Induction Melting Furnace

- Usage

- Industrial Metal Melting

- Power

- Up to 250 kW

- Voltage

- 380-440 V

- Size

- Customizable as per requirement

- Dimensions

- Varies as per capacity

- Weight

- Depends on model (starts at 200 kg)

- Application

- Melting Iron, Steel, Copper, Aluminum

- Fuel Type

- Electric (Induction)

- Capacity

- 10 kg to 2000 kg

- After-Sales Support

- Comprehensive Maintenance and Service

- Body Material

- Heavy Duty MS Structure

- Installation Service

- Available

- Melting Temperature Range

- Up to 1700°C

- Safety Features

- Overheat Protection, Emergency Stop, Interlocks

- Operator Requirement

- 1-2 personnel

- Stirring Mechanism

- Optional Electromagnetic Stirring

- Crucible Type

- Graphite/Clay/Customized

- Control Panel

- Digital PLC Control Panel

- Automation

- Semi-Automatic/Automatic

- Cooling System

- Water Cooled

- Environment Compliance

- Meets International Standards

Induction Melting Furnace Assembly Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

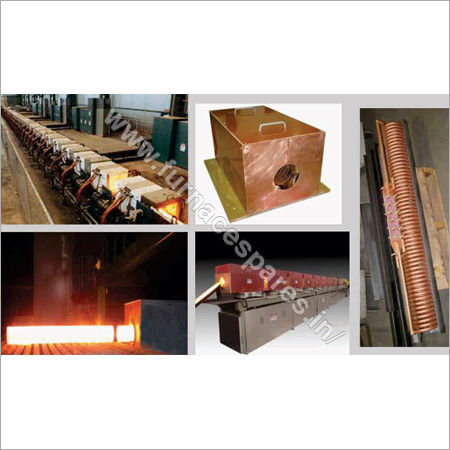

About Induction Melting Furnace Assembly

Having excellent industrial knowledge of this domain, we have been engaged in manufacturing and supplying supreme grade Induction Melting Furnace Assembly. This assembly is used for manufacturing induction melting furnace and ensuring its smooth functionality. Offered assembly is available in different specifications as per client's requirements. Provided assembly is highly cherished among clients due to its robustness, excellent strength, less maintenance, corrosion resistant surface and enhanced durability. This assembly is manufactured using quality approved components by our experienced professionals with latest innovations techniques. Additionally, this Induction Melting Furnace Assembly are safely packed to prevent damage.

Efficient and Precise Melting

Experience fast and uniform melting with this induction furnace, capable of reaching up to 1700C. The digitally controlled PLC panel ensures precise temperature management, while the heavy-duty construction guarantees durability. Its low energy consumption and ergonomic design make it suitable for a wide range of metal applications, including melting iron, steel, copper, and aluminum.

Safety and Compliance Focused

The system incorporates robust safety features such as overheat protection, emergency stop, and integrated interlocks, ensuring operator and facility safety. The furnace complies with international environmental standards, making it a reliable choice for industries mindful of regulatory obligations.

Tailored Solutions and Comprehensive Support

With installation and operator training available, the furnace is customizable in size, crucible type, and capacity, meeting unique industrial requirements. Comprehensive maintenance and after-sales services are provided, enabling smooth and uninterrupted operation throughout the equipment's lifecycle.

FAQ's of Induction Melting Furnace Assembly:

Q: How does the induction melting furnace achieve high melting efficiency?

A: This furnace uses electric induction with up to 250 kW power and an advanced digital PLC control panel to provide fast, uniform, and precise metal melting at temperatures up to 1700C, resulting in high energy efficiency and reduced melting times.Q: What metals can be melted in this induction furnace assembly?

A: The furnace is suitable for melting a broad range of metals, including iron, steel, copper, and aluminum, making it ideal for various industrial applications.Q: When is installation and operator training available for this furnace?

A: Installation services and operator training are provided after purchase, with scheduling tailored to the customer's requirements to ensure effective and safe commissioning.Q: Where can the induction melting furnace be installed?

A: This furnace is designed for industrial environments in compliance with international standards. Its dimensions and configuration are customizable to fit specific plant layouts and space constraints.Q: What is the process for operating the furnace and ensuring safety?

A: Operation involves setting parameters through the PLC control panel; built-in safety features like overheat protection, emergency stop, and interlocks safeguard users. Only 1-2 trained operators are required to supervise the melting process.Q: How does the cooling system work in the furnace assembly?

A: The integrated water-cooled system dissipates generated heat efficiently, maintaining optimal temperatures for the furnace body and prolonging equipment life.Q: What are the key benefits of choosing this induction melting furnace?

A: Key advantages include customizable capacity, rapid melting, precise temperature control, ergonomic design, low operational energy consumption, and comprehensive after-sales support, making it a reliable investment for industrial metal melting needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Furnace Assembly Category

Induction Heating Furnace Spares

Minimum Order Quantity : 10 Pieces

Size : Customizable as per furnace model

Feature : Durable, Corrosion Resistant, Precision Engineered

Voltage : 220480V

Weight : Depends on Spare Part Type

Induction Heating Coils

Minimum Order Quantity : 10 Pieces

Size : Customized as per requirement

Feature : Precise Heating, Fast Response, Energy Saving

Voltage : 220V / 380V / 415V AC

Weight : Varies with Model

Induction Melting Coil

Minimum Order Quantity : 10 Pieces

Size : Customized as per requirement

Feature : Corrosion resistant, Energy efficient, Uniform heating

Voltage : 220V/380V/440V

Weight : As per coil size and design

Induction Furnace Assembly

Minimum Order Quantity : 10 Pieces

Size : Customizable as per requirement

Feature : Energy Efficient, Rapid Melting, Temperature Control

Voltage : 380 V 415 V

Weight : Depends on model and capacity

Send Inquiry

Send Inquiry