Induction Furnace Coil

Induction Furnace Coil Specification

- Rating

- Three Phase Induction

- Feature

- High Efficiency, Durable, Corrosion Resistant

- Condition

- New

- Type

- Induction Furnace Coil

- Usage

- Industrial Furnace Heating

- Power

- 50 kW to 2000 kW

- Voltage

- 380 V to 440 V

- Size

- Customizable as per requirement

- Dimensions

- As per design/application

- Weight

- Depending on design and capacity

- Application

- Metal Melting and Heating

- Fuel Type

- Electric

- Capacity

- Upto 5 Tons

- Connection Type

- Flanged/Bolted

- Mounting Type

- Horizontal/Vertical

- Insulation Material

- Fiberglass/Asbestos/ceramic sleeve

- Material

- Electrolytic Copper Tubing

- Surface Finish

- Polished/Coated

- Operating Temperature

- Up to 1750°C

- Coil Shape

- Helical/Spiral

- Cooling System

- Water Cooled

- Frequency Range

- 50 Hz - 10 kHz

Induction Furnace Coil Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Induction Furnace Coil

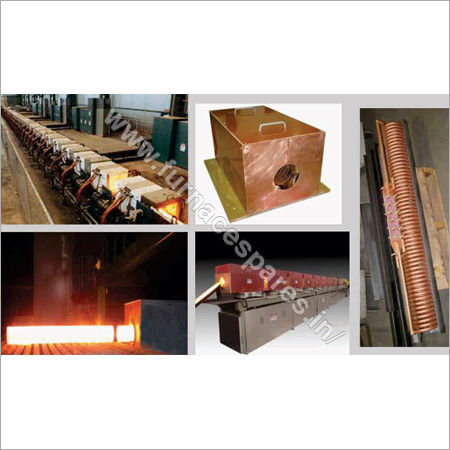

We are a well-known firm in this domain, engrossed in manufacturing and supplying quality assured Induction Furnace Coil. This coil is used for heating furnace in fastest possible manner. Offered coil is manufactured using high grade components under guidance of our dexterous professionals at ultra-modern production unit. Provided coil finds its applications in manufacturing industries to be installed in induction furnace. Offered coil is highly cherished among clients for its smooth functionality, enhanced durability, rust resistant surface, defect free body and excellent strength. In addition to this, provided Induction Furnace Coil can be purchased from us in numerous specifications according to requirements of clients.

Superior Performance for Industrial Heating Needs

Our induction furnace coils deliver efficient and uniform heating, making them suitable for industrial-scale metal melting. Their high-power capacity and customizable designs cater to various industrial demands, ensuring stable and rapid operation even in rigorous environments.

Durable Materials and Advanced Cooling

Manufactured from electrolytic copper tubing, the coils feature water-cooled systems and robust insulation, including fiberglass, asbestos, or ceramic sleeves. This design guarantees long service life, superior heat resistance, and enhanced corrosion protection.

Flexible Design and Easy Installation

Available in both helical and spiral shapes, the coils can be mounted horizontally or vertically. With customizable sizes and various connection types (flanged or bolted), installation is straightforward and adaptable to existing systems and diverse applications.

FAQ's of Induction Furnace Coil:

Q: How does the water-cooled system benefit the induction furnace coil's performance?

A: The water-cooled system efficiently dissipates heat generated during operation, maintaining optimal coil temperature. This prevents overheating, enhances coil lifespan, and ensures consistent performance, especially during prolonged industrial use.Q: What materials are used for the coil tubing and insulation, and why are they chosen?

A: The coil uses electrolytic copper tubing for excellent electrical conductivity, while insulation can be fiberglass, asbestos, or ceramic sleeve, all selected for their high-temperature resistance and electrical insulation properties, ensuring safety and durability.Q: When should the induction furnace coil be replaced or serviced?

A: Regular inspection is recommended, especially in high-usage settings. The coil should be serviced or replaced if there are signs of reduced heating efficiency, physical damage, or insulation wear, typically after prolonged operation or according to the manufacturer's maintenance schedule.Q: Where can these induction furnace coils be installed?

A: They are designed for installation in industrial settings such as metal foundries, manufacturing plants, and other environments requiring metal melting or heating. Their horizontal or vertical mounting options make them adaptable to most furnace configurations.Q: What is the process for customizing coil dimensions and capacity?

A: Customers can provide specific application requirements-such as capacity, power range, and dimensional constraints. The manufacturer then designs and fabricates coils tailored to those needs, ensuring a perfect fit for the intended furnace system.Q: How is the induction furnace coil typically used in metal melting operations?

A: The coil generates a magnetic field when energized, inducing eddy currents in the metal load. This results in rapid and even heating, making the process energy-efficient and suitable for continuous industrial production.Q: What are the primary benefits of using this induction furnace coil?

A: Key benefits include high heating efficiency, rapid temperature rise, uniform heat distribution, durability against high operating temperatures, effective corrosion resistance, and flexible installation options to suit varied industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Furnace Assembly Category

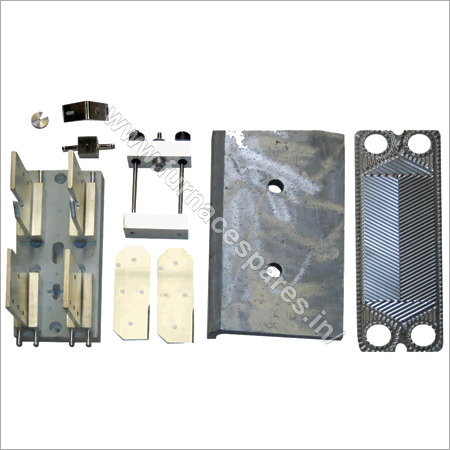

Induction Furnace Parts

Minimum Order Quantity : 10 Pieces

Dimensions : Vary depending on part

Feature : Corrosion Resistant, Durable, Precision Engineered

Condition : New

Capacity : Varies by part

Induction Heating Coils

Minimum Order Quantity : 10 Pieces

Dimensions : As Per Design

Feature : Precise Heating, Fast Response, Energy Saving

Condition : New

Capacity : As Required

Induction Furnace Components-CONTROL CIRCUIT CARD FOR PANEL

Minimum Order Quantity : 10 Pieces

Dimensions : Customized as per panel

Feature : High Reliability, Precision Control

Condition : New

Capacity : Supports MultiRelay Outputs

Induction Melting Coil

Minimum Order Quantity : 10 Pieces

Dimensions : According to specifications

Feature : Corrosion resistant, Energy efficient, Uniform heating

Condition : New

Capacity : 5 Kg to 500 Kg

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free