Induction Heating Coils

Induction Heating Coils Specification

- Feature

- Precise Heating, Fast Response, Energy Saving

- Rating

- High Efficiency

- Condition

- New

- Type

- Induction Heating Coil

- Usage

- Industrial Heater

- Power

- 5 kW - 100 kW

- Voltage

- 220V / 380V / 415V AC

- Size

- Customized as per requirement

- Dimensions

- As Per Design

- Weight

- Varies with Model

- Application

- Heat Treatment, Brazing, Soldering, Forging

- Fuel Type

- Electric

- Capacity

- As Required

- Coil Material

- Copper Tubing with High Conductivity

- Temperature Range

- Up to 1200°C

- Frequency

- 10 kHz - 500 kHz

- Cooling Method

- Water Cooled

- Compatibility

- Suitable for Various Induction Heating Machines

- Customization

- Designs for Rectangle, Spiral, Pancake, or Customized Shapes

- Connection Type

- Terminal or Cable Ends

- Insulation

- High-Temperature Insulation Coating

- Surface Finish

- Epoxy or Varnish Coated

Induction Heating Coils Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

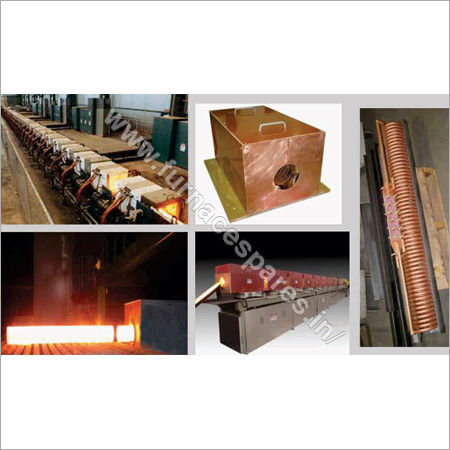

About Induction Heating Coils

Our production unit is fully equipped with all required machinery and trained personnel, helping us to manufacture and supply an exclusive range of Induction Heating Coils. These coils are ideal option for heating iron, copper and steel at metallurgical industries. To manufacture the coils, we use superior quality materials, procured from the certified vendors. The clients can avail our Induction Heating Coils in different power capacities and specifications as to suit their requirements.

Features:

-

High efficiency

-

Easy installation

-

Lightweight

High-Efficiency Copper Induction Coils

Our induction heating coils are designed using premium copper tubing for optimal conductivity and performance in a range of industrial heating tasks. Featuring advanced insulation and precise manufacturing, these coils support high-efficiency operations with minimal energy loss and rapid heat response. All coils are water-cooled to manage elevated temperatures and maintain their durable construction.

Custom Design & Application Versatility

Choose from spiral, rectangular, pancake, or specialized coil forms tailored to your application. Our customized solutions ensure compatibility with a variety of induction heating equipment, making them suitable for heat treatment, soldering, brazing, and forging processes. Whatever your specification, we provide coils in the exact size and capacity you require.

Reliable & Energy Saving Performance

Engineered to deliver consistent and repeatable heating, these coils operate smoothly across a broad frequency and power range. Superior insulation and energy-efficient design minimize operational costs, while epoxy or varnish surface coatings ensure longer coil life and environmental resistance.

FAQ's of Induction Heating Coils:

Q: How are induction heating coils cooled during operation?

A: These coils utilize a water-cooling method to efficiently manage the heat generated during intensive industrial processes. The cooling system helps maintain operational temperatures, protects the coil's integrity, and extends its service life.Q: What materials are used for the construction of these induction heating coils?

A: High-conductivity copper tubing is used as the core material for exceptional electrical and thermal performance. The coils are coated with high-temperature insulation for enhanced safety and efficiency, with additional epoxy or varnish surface finishes available.Q: When should I consider customizing the coil shape or size?

A: Customization is recommended when you need the coil to fit specific machines or unique heating tasks, such as irregular components or targeted heat zones. Shapes like spiral, rectangle, pancake, or tailored geometries can be produced according to your requirements.Q: Where can these induction heating coils be used?

A: These coils are suitable for a wide array of applications across industries for heat treatment, brazing, soldering, or forging. They are compatible with multiple induction heating machines and can be exported, supplied, and installed across India and to international markets.Q: What benefits do epoxy or varnish coatings provide to the coils?

A: Epoxy or varnish surface coatings offer additional protection against moisture, oxidation, and mechanical wear, enhancing the coil's durability and service life, especially in demanding industrial environments.Q: How do I select the right voltage and power rating for my induction heating coil?

A: The choice depends on your specific application needs and the available electrical infrastructure, with options ranging from 220V to 415V AC and power capacities from 5 kW to 100 kW. Our technical team can help you determine the optimal configuration based on your process requirements.Q: What processes can these coils be used for in industrial settings?

A: Induction heating coils are ideal for processes such as heat treatment, brazing, soldering, and forging. Their energy-efficient, rapid-heating properties ensure consistent and controllable heating for a variety of workpieces and production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Furnace Assembly Category

Induction Heating Furnace Spares

Minimum Order Quantity : 10 Pieces

Dimensions : As per the required parts

Feature : Durable, Corrosion Resistant, Precision Engineered

Power : High Power Compatible

Capacity : Suitable for up to 10 Ton Furnaces

Induction Melting Furnace Assembly

Minimum Order Quantity : 10 Pieces

Dimensions : Varies as per capacity

Feature : Low energy consumption, Fast melting, Ergonomic design, Precise temperature control

Power : Up to 250 kW

Capacity : 10 kg to 2000 kg

Induction Furnace Spare Parts

Minimum Order Quantity : 10 Pieces

Dimensions : Custom / Standard

Feature : High Durability, Corrosion Resistant, Precision Engineered

Power : Up to 650 kW

Capacity : Varies by part

Induction Furnace Components-CONTROL CIRCUIT CARD FOR PANEL

Minimum Order Quantity : 10 Pieces

Dimensions : Customized as per panel

Feature : High Reliability, Precision Control

Power : Low Power Consumption

Capacity : Supports MultiRelay Outputs

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free