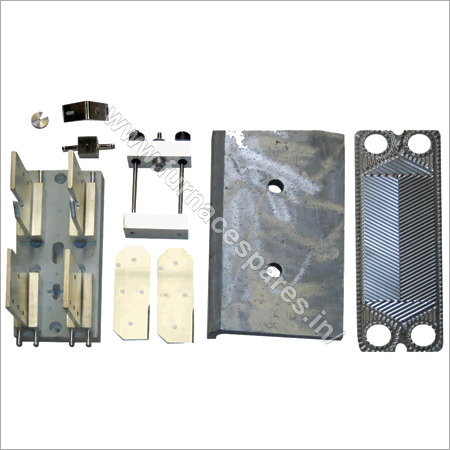

Induction Furnace Parts

Induction Furnace Parts Specification

- Rating

- High Performance

- Feature

- Corrosion Resistant, Durable, Precision Engineered

- Condition

- New

- Type

- Spare Parts

- Usage

- Industrial

- Power

- Applicable as per furnace capacity

- Voltage

- Suitable for standard induction furnaces

- Size

- Standard, As per furnace model

- Dimensions

- Vary depending on part

- Weight

- Depends on specific part

- Application

- Induction Furnace Maintenance & Repair

- Fuel Type

- Electric

- Capacity

- Varies by part

- Lifespan

- Long operational life

- Color

- Metallic, as per part

- Packaging

- Safe export-standard packaging

- Surface Treatment

- Polished/Coated

- Compatibility

- All major induction furnace brands

- Material

- High quality metal alloy, Copper, Steel, or as required

- Heat Resistance

- Up to 1800°C (varies by part)

- Standards Followed

- IS, ASTM, or OEM standards

- Lead Time

- Immediate to 7 working days

- Installation

- Easy to assemble and replace

Induction Furnace Parts Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- Standard Packaging

About Induction Furnace Parts

Within a very short period of 4 years, we have established ourselves as a leading manufacturers and suppliers of Induction Furnace Parts. These parts are manufactured under the firm observation of the expert professionals, using high quality materials. Our parts are checked on durability and quality parameters to provide a defect free range to the clients. The clients can avail our Induction Furnace Parts at the cost effective prices from us.

Features:

- Rust proof finishing

- Sturdy design

- Easy to install

Premium Materials and Engineering

Induction Furnace Parts are crafted using high-grade metal alloys, copper, and steel for superior thermal conductivity and durability. Each part undergoes specialized surface treatment-polished or coated-to withstand high-temperature operations and prevent corrosion, ensuring peak performance in industrial environments.

Versatile Compatibility and Standards

Designed to integrate seamlessly with all major induction furnace brands, these spare parts meet strict IS, ASTM, or OEM standards for quality and safety. Whether required for routine maintenance or specific repairs, each component offers precise fitment and adaptability to varying furnace models and capacities.

Reliability with Easy Installation

Every part is precision-engineered for simple assembly and swift replacement, reducing downtime during maintenance or upgrades. Adhering to export-standard packaging protocols, each shipment arrives secure and ready for immediate use, supporting uninterrupted industrial operations.

FAQ's of Induction Furnace Parts:

Q: How are the induction furnace parts installed and replaced?

A: Our induction furnace parts are specifically designed for easy installation and replacement. They are dimensioned according to standard furnace models and come with clear instructions, allowing maintenance teams to assemble and swap out parts with minimal downtime.Q: What materials are used in these furnace parts and how does this benefit the user?

A: We utilize premium metal alloys, copper, steel, or other materials as required for each part. These materials provide excellent thermal conductivity, corrosion resistance, and long operational life, ensuring reliable furnace performance under demanding conditions.Q: When should I consider replacing induction furnace spare parts?

A: It is recommended to replace furnace parts during scheduled maintenance or when you notice a decline in performance, increased wear, or visible damage. Regular replacement helps maintain safety, efficiency, and prolongs the overall life of your induction furnace.Q: Where do the furnace parts originate, and can they be shipped internationally?

A: We are an exporter, manufacturer, supplier, and trader based in India. All parts are packaged according to export-standard protocols, allowing us to ship reliably to customers worldwide.Q: What is the typical lead time for delivery and how are the parts packaged?

A: Lead times range from immediate dispatch to a maximum of 7 working days. Each part is packaged using safe, export-standard packaging to ensure it arrives in pristine condition, ready for use in industrial applications.Q: What process is followed to ensure part compatibility and quality?

A: Components are engineered to match IS, ASTM, or OEM standards and tailored for all major induction furnace brands. Every part undergoes precise quality checks and surface treatment to guarantee durability, high heat resistance, and reliable performance.Q: How do these spare parts improve furnace operation and maintenance?

A: Using our precision-engineered, corrosion-resistant, and heat-tolerant furnace parts helps maintain high furnace efficiency, reduces maintenance downtime, and extends the service life of critical equipment, supporting optimized industrial performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Furnace Assembly Category

Induction Furnace Components-CONTROL CIRCUIT CARD FOR PANEL

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial Panel Control

Type : Control Circuit Card

Voltage : 24V DC

Capacity : Supports MultiRelay Outputs

Induction Furnace Assembly

Minimum Order Quantity : 10 Pieces

Usage : Other, Metal Melting

Type : Coreless Induction Furnace Assembly

Voltage : 380 V 415 V

Capacity : 50 Kg to 10 Tons

Induction Furnace Assembly Parts

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial Melting and Heating

Type : Furnace Assembly Parts

Voltage : 380415V (Customizable)

Capacity : Compatible with 100 kg15 ton induction furnaces

Induction Heating Furnace Spares

Minimum Order Quantity : 10 Pieces

Usage : Other, Induction Heating Furnace

Type : Spare Parts Kit

Voltage : 220480V

Capacity : Suitable for up to 10 Ton Furnaces

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free