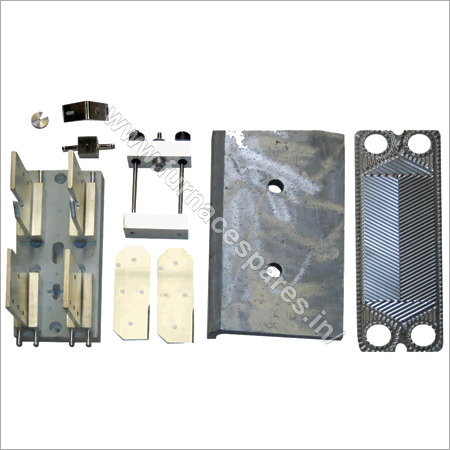

Induction Furnace Assembly

MOQ : 10 Pieces

Induction Furnace Assembly Specification

- Rating

- Up to 3500 kW

- Feature

- Energy Efficient, Rapid Melting, Temperature Control

- Condition

- New

- Type

- Coreless Induction Furnace Assembly

- Usage

- Metal Melting

- Power

- Electric

- Voltage

- 380 V - 415 V

- Size

- Customizable as per requirement

- Dimensions

- Varies with model and capacity

- Weight

- Depends on model and capacity

- Application

- Steel, Iron, Copper, Aluminum, Gold Melting

- Fuel Type

- Electric (Induction)

- Capacity

- 50 Kg to 10 Tons

- Applicable Metals

- Ferrous and Non-ferrous metals

- Crucible Type

- High-grade fused silica or graphite lining

- Melting Time

- 30-60 minutes depending on capacity

- Control Panel

- Digital PLC-based Automation

- Installation

- On-site installation and commissioning available

- Thermal Protection

- Integrated over-temperature protection

- Induction Coil

- High-conductivity copper windings

- Furnace Shell Material

- Heavy-duty MS/SS fabricated structure

- Power Supply Frequency

- Medium Frequency (500 Hz - 10 kHz)

- Efficiency

- High thermal efficiency, Low heat loss

- Temperature Range

- Up to 1600°C

- Safety Features

- Over-current, over-voltage, and leakage protection

- Cooling System

- Closed-Loop Water Cooling

- Tilting Mechanism

- Hydraulic or Motorized Tilting

Induction Furnace Assembly Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Induction Furnace Assembly

Since our inception in the year 2010, we have successfully been engaged in manufacturing, exporting and supplying a wide range of best quality Induction Furnace Assembly. The offered assembly is used in modern foundries to melt aluminium, iron, copper, steel and other metals. The provided assembly is manufactured by utilizing high grade components and latest techniques under experts' guidance at our premises. In addition to this, the provided Induction Furnace Assembly is available for our esteemed clients at reasonable prices.

Features:

Features:

- Robust construction

- High performance

- Energy efficient

- Longer service life

High-Performance Metal Melting Solution

This induction furnace system is designed for energy-efficient, low-loss melting of a wide variety of metals, including steel, iron, copper, aluminum, and gold. With high-grade fused silica or graphite lining and a powerful PLC-controlled panel, it delivers precise temperature control up to 1600C. Suitable for industrial applications, it ensures both rapid melting and reliable safety features.

Customizable and Robust Construction

Constructed using heavy-duty MS/SS, the furnace's shell is engineered for longevity and structural integrity, while the induction coil is made from high-conductivity copper. The unit supports hydraulic or motorized tilting, closed-loop cooling, and comes in various capacities from 50 kg to 10 tons. Custom sizing and on-site installation options are offered to suit specific customer requirements.

FAQ's of Induction Furnace Assembly:

Q: How does the closed-loop water cooling system benefit the induction furnace operation?

A: The closed-loop water cooling system efficiently maintains optimal temperature for the furnace components, helping prevent overheating and ensuring consistent operation. This system also reduces water consumption and minimizes the risk of scale or contamination, prolonging equipment life and enhancing safety.Q: What metals can be melted using this induction furnace assembly?

A: This induction furnace is versatile and capable of melting both ferrous and non-ferrous metals, including steel, iron, copper, aluminum, and gold. Its high-temperature range and coreless design make it suitable for various industrial metal processing tasks.Q: When is on-site installation and commissioning available for this furnace?

A: On-site installation and commissioning are available as part of the service provided by the manufacturer, exporter, or supplier in India. These services are scheduled based on customer requirements and completion of site readiness, ensuring proper setup and operational training.Q: Where is the furnace typically installed and used?

A: The induction furnace assembly is typically installed in foundries, metalworking industries, and manufacturing plants throughout India and internationally. Its robust build and customizable dimensions allow adaptation to different workshop layouts and melting needs.Q: What is the process for controlling and adjusting the melting temperature?

A: The digital PLC-based automation panel provides precise control over the furnace's operating temperature. Operators can set and monitor the melting temperature (up to 1600C), adjust parameters as needed, and utilize integrated safety alarms for over-temperature protection.Q: How does the high-grade crucible lining contribute to furnace efficiency?

A: Using high-grade fused silica or graphite crucible linings enhances thermal efficiency, reduces heat loss, and improves the purity of the molten metal. These materials withstand extreme temperatures while minimizing contamination and extending crucible lifespan.Q: What are the main benefits of choosing this induction furnace for metal melting?

A: Key benefits include rapid melting times (as fast as 30-60 minutes), high thermal efficiency, safe and automated operation, and a customizable design that accommodates a range of capacities and installation requirements. Integrated safety systems ensure reliable performance and operator protection.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Induction Furnace Assembly Category

Induction Furnace Parts

Minimum Order Quantity : 10 Pieces

Rating : High Performance

Usage : Other, Industrial

Condition : New

Dimensions : Vary depending on part

Spare Part Induction Furnace

Minimum Order Quantity : 10 Pieces

Rating : Industrial Grade

Usage : Other, Industrial Furnace Maintenance

Condition : New

Dimensions : As per part specifications

Induction Melting Furnace Assembly

Minimum Order Quantity : 10 Pieces

Rating : High Efficiency

Usage : Other, Industrial Metal Melting

Condition : New

Dimensions : Varies as per capacity

Induction Furnace Coil

Minimum Order Quantity : 10 Pieces

Rating : Three Phase Induction

Usage : Other, Industrial Furnace Heating

Condition : New

Dimensions : As per design/application

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free