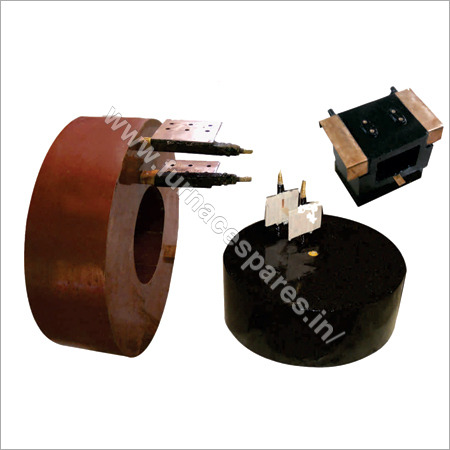

Current Limiting Reactor

Current Limiting Reactor Specification

- Feature

- High Durability, Low Power Loss, Robust Design

- Rating

- Up to 33 kV, 3150A

- Condition

- New

- Type

- Current Limiting Reactor

- Usage

- Industrial, Electrical Distribution

- Power

- As per application

- Voltage

- Up to 33 kV

- Size

- Customizable as per requirement

- Dimensions

- As per design

- Weight

- Depends on capacity & design

- Application

- Power Distribution, Short-Circuit Current Limiting

- Capacity

- As per customer specification

- Material

- Copper / Aluminium Winding with Laminated Core

- Ambient Temperature

- -10°C to +45°C

- Impedance Range

- 2% - 30%

- Mounting Type

- Floor Mounted

- Terminal Type

- Stud / Busbar

- Frequency

- 50 Hz/60 Hz

- Enclosure

- IP23 / IP54 (on request)

- Cooling Type

- Air Cooled / Oil Cooled

- Phase

- Three Phase

- Insulation Class

- Class F / H

- Standards

- IS 5553, IEC 60076-6

Current Limiting Reactor Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Current Limiting Reactor

We have gained huge appreciation from our clients for manufacturing and supplying high quality Current Limiting Reactor. This reactor is used for protecting system components from high current levels and limiting inrush current when starting a large motor. Provided reactor is well suited for reducing short-circuit current. Offered reactor is manufactured using fine grade components by our adroit professionals with latest innovative techniques. Provided reactor is known for its hassle free working, less noisy operation and minimum maintenance. In addition, clients can purchase this Current Limiting Reactor from us in various specifications.

Optimized for Short-Circuit Limitation

The current limiting reactor provides essential protection by restricting short-circuit currents in electrical networks, thereby safeguarding equipment and enhancing operational stability. Its robust build and custom impedance range (2-30%) allow seamless adaptation to diverse load conditions, ensuring safe and reliable system operation. Perfectly suited for industrial and power distribution environments, it ensures process continuity and protection for critical assets.

Engineered for Versatility and Durability

Manufactured as per IS 5553 and IEC 60076-6, the reactor accommodates a wide array of operational requirements. Choose between air or oil cooling, copper or aluminium windings, and floor-mounted installation to match your infrastructure. Durable enclosure options (IP23/IP54) and insulation (Class F/H) guarantee longevity, even in challenging environments. Its customizable size and ratings make it fit for any industrial specification.

FAQ's of Current Limiting Reactor:

Q: How does a current limiting reactor enhance electrical system protection?

A: A current limiting reactor restricts short-circuit currents, mitigating the risk of damage to transformers, switchgear, and cables. By controlling inrush and fault currents, it safeguards connected equipment, improving overall safety and reducing potential downtime.Q: What factors should be considered when selecting the cooling type for a reactor?

A: Selection between air cooled and oil cooled depends on the installation environment, load profile, and cooling requirements. Air-cooled reactors are ideal for well-ventilated indoor settings, whereas oil-cooled reactors yield better thermal management for high capacity or continuous operation.Q: When is it beneficial to opt for copper versus aluminium windings in these reactors?

A: Copper windings are preferred for higher efficiency and compact designs due to superior conductivity, while aluminium winding offers a cost-effective solution with lighter weight. The choice depends on your budget, thermal constraints, and size requirements.Q: Where are these current limiting reactors typically installed in a power distribution system?

A: They are floor-mounted near switchgear, transformers, or distribution panels where managing and isolating high fault currents is critical. Proper placement ensures optimum performance and convenient integration into industrial power infrastructures.Q: What is the standard process for customizing a reactor to meet specific requirements?

A: Customization involves assessing your electrical parameters, space constraints, ambient conditions, and desired impedance. Once requirements are determined, design and manufacturing follow IS 5553 and IEC 60076-6 standards, ensuring the reactor meets precise operational needs.Q: How is the reactor's size and rating determined for an application?

A: These parameters are based on system voltage (up to 33 kV), required current (up to 3150A), desired impedance (2-30%), and installation space. Engineers collaborate with customers to select the optimal size, rating, and design for reliability and efficiency.Q: What are the key benefits of installing a current limiting reactor from your range?

A: Our reactors boast high durability, robust construction, low power loss, and flexible design. They comply with strict industry standards, protect valuable equipment, and adapt to any industrial application, thus ensuring operational safety and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Melting Spare Parts Category

Electromagnetic Components

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial

Application : Electrical Assemblies, Automation, Control Panels

Feature : Durable, High Efficiency, Low Maintenance

Melting Induction Furnace

Minimum Order Quantity : 10 Pieces

Usage : Other, Metal Melting

Application : Foundry, Metal Casting, Industrial Melting Operations

Feature : Energy Efficient, Fast Melting, Compact Design, Advanced Temperature Control

Inductotherm Melting Furnace Spares

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial

Application : Induction Melting Furnace

Feature : Corrosion Resistant, Accurate Fit, Durable

Aluminium Plate Casting

Minimum Order Quantity : 10 Pieces

Usage : Other, For Machinery and Structural Applications

Application : Used in heavy engineering, manufacturing, and construction

Feature : Corrosion Resistant, High Strength, Durable

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free