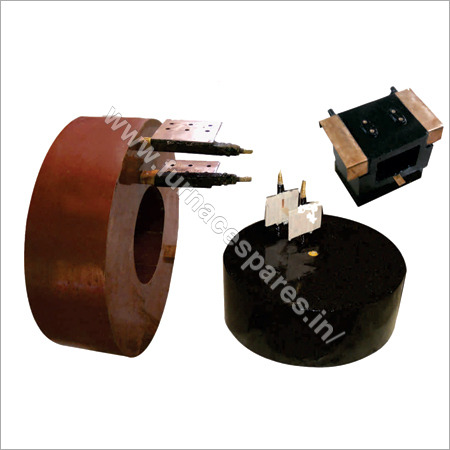

Inductotherm Melting Furnace Spares

Inductotherm Melting Furnace Spares Specification

- Rating

- High Performance

- Feature

- Corrosion Resistant, Accurate Fit, Durable

- Condition

- New

- Type

- Induction Furnace Spare Part

- Usage

- Industrial

- Power

- As per Furnace Specification

- Voltage

- 220V-440V

- Size

- Standard/Custom

- Dimensions

- As per Drawing/Requirement

- Weight

- Varies as per Part

- Application

- Induction Melting Furnace

- Fuel Type

- Electric

- Capacity

- Upto 25 Tons

- Compatibility

- Inductotherm and Equivalent Furnaces

- Packaging

- Export Quality Packaging

- Spare Parts Offered

- Water Cooled Cable, Hoses, Bus Bar, Crucible Support, Clamps, Contact Pads, Hydraulic Spares, Power Connectors, etc.

- Operating Temperature

- Up to 1500°C

- Material

- High-grade Metal Alloys

- Color

- Metallic/Grey/As supplied

- Surface Finish

- Polished/Coated

Inductotherm Melting Furnace Spares Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Inductotherm Melting Furnace Spares

Backed with rich industrial experience and knowledge, we have been engrossed in manufacturing and supplying premium grade Electrotherm furnace spares. These spares are available in various specifications as per client's demand. Offered spares are used in assembly of furnace and ensure its smooth functionality. Easy to install and require less maintenance, provided spares are highly appreciated among clients. These spares are also known for their accurate dimension, robust construction, corrosion resistant surface, user-friendly design and optimum strength. Apart from this, offered Electrotherm furnace spares are safely packed for avoiding damage during transit.

Electrotherm furnace spares are being offered by us to meet specific requirements of clients. We basically deal in copper and copper based alloys induction furnace. These products are engineered industrially using

Absolute offers spares and services for all types of furnaces.

The spares offers are mainly,

1. Heaters for Electrically Fired furnaces

2. Ceramic Tubes

3. Ceramic Bricks

We have capacity to manufacture Induction Melting coil range from 100 Kgs to 40, 000 kgs capacity.

Comprehensive Range of Spare Parts

Our selection includes water cooled cables, hoses, bus bars, crucible supports, clamps, contact pads, hydraulic spares, and power connectors. Each spare is engineered for high performance and corrosion resistance, designed to meet the rigorous demands of induction melting furnace operations.

Custom and Standard Solutions

Available in both standard dimensions and custom specifications, our furnace spares cater to varying industrial requirements. We manufacture each part according to detailed drawings or specific application needs, ensuring seamless integration with your existing equipment.

Reliable Quality and Export Packaging

Constructed from high-grade metal alloys, each spare part is finished with polished or protective coatings and undergoes strict quality checks. Export-quality packaging safeguards components during transit, providing clients with reliable, ready-to-use products upon delivery.

FAQ's of Inductotherm Melting Furnace Spares:

Q: What types of spare parts are available for Inductotherm Melting Furnaces?

A: We offer a comprehensive range of spares such as water cooled cables, hoses, bus bars, crucible supports, clamps, contact pads, hydraulic spares, and power connectors. All parts are suitable for Inductotherm and equivalent furnaces and are designed for industrial applications.Q: How are custom-sized spare parts manufactured for unique furnace requirements?

A: Custom-sized parts are manufactured based on client-supplied drawings or specifications. Our technical team ensures that each piece is tailored to fit accurately and function optimally with your specific furnace setup.Q: When should I replace spare parts in my induction melting furnace?

A: Regular inspection is recommended, especially for high-wear components operating at elevated temperatures. Replace parts if you notice signs of wear, corrosion, or performance decline to maintain furnace efficiency and prevent downtime.Q: Where do you supply and export these furnace spares?

A: We are based in India, serving clients nationwide as well as exporting to international markets. Our packaging meets export quality standards to ensure all parts arrive safely at their destination.Q: What is the process for ordering and receiving these spares?

A: To order, provide us with the required part specifications or drawings. Once confirmed, we proceed with manufacturing, quality checks, and export-quality packaging for secure delivery to your location.Q: How do these spares benefit my induction furnace operations?

A: Using our high-performance, corrosion-resistant spares enhances your furnace's durability, accuracy, and operational reliability. This minimizes maintenance costs and prolongs equipment lifespan.Q: Can these spares handle high operating temperatures and different power requirements?

A: Yes, all spares are fabricated from high-grade metal alloys with polished or coated finishes, ensuring performance at temperatures up to 1500C and compatibility with power ratings from 220V to 440V as per furnace specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Melting Spare Parts Category

Electromagnetic Components

Minimum Order Quantity : 10 Pieces

Size : Standard

Usage : Other, Industrial

Application : Electrical Assemblies, Automation, Control Panels

Melting Induction Furnace

Minimum Order Quantity : 10 Pieces

Size : Customizable

Usage : Other, Metal Melting

Application : Foundry, Metal Casting, Industrial Melting Operations

Current Limiting Reactor

Minimum Order Quantity : 10 Pieces

Size : Customizable as per requirement

Usage : Other, Industrial, Electrical Distribution

Application : Power Distribution, ShortCircuit Current Limiting

Frp Insulation Material

Minimum Order Quantity : 10 Pieces

Size : Customizable

Usage : Other, Industrial and Commercial

Application : Electrical Insulation, Construction, Panels, Cable Tray

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free