Melting Induction Furnace

Melting Induction Furnace Specification

- Feature

- Energy Efficient, Fast Melting, Compact Design, Advanced Temperature Control

- Rating

- High Efficiency

- Condition

- New

- Type

- Industrial Melting Induction Furnace

- Usage

- Metal Melting

- Power

- 100 kW - 600 kW

- Voltage

- 380 V / 415 V / 440 V

- Size

- Customizable

- Dimensions

- As per model (custom sizes available)

- Weight

- Depends on model, ranges from 500 kg to 4000 kg

- Application

- Foundry, Metal Casting, Industrial Melting Operations

- Fuel Type

- Electric (Induction)

- Capacity

- 30 kg - 3000 kg

- Frequency Range

- 500 Hz - 10000 Hz

- Automation Grade

- Semi-Automatic / Fully Automatic

- Safety Features

- Overload Protection, Emergency Stop, Insulation Monitoring

- Cooling System

- Water Cooled

- Control Panel

- Microprocessor/Digital Controller

- Environmental Compliance

- Low Emission, Eco-friendly Operation

- Service Voltage Tolerance

- ±10%

- Crucible Type

- Magnesium/Graphite/Silicon Carbide

- Installation

- On-Site Support Available

- Color

- Industrial Grey / Blue

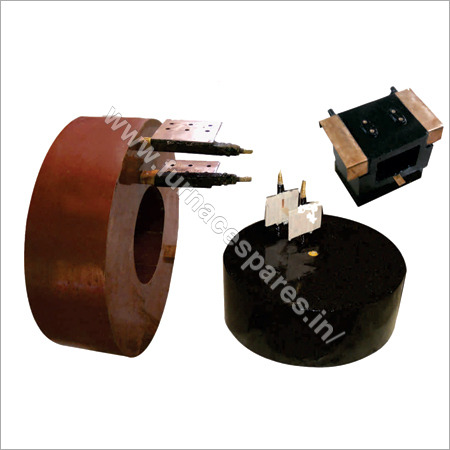

- Induction Coil Material

- High Quality Copper

- Melting Time

- 25 mins to 60 mins per charge

Melting Induction Furnace Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Melting Induction Furnace

We are engaged in manufacturing and supplying top notch range of Melting Induction Furnace. Offered furnace is used for heating materials and objects at very high temperature. Provided furnace is manufactured using quality approved components by our adept professionals at modern production unit. This furnace is available in numerous specifications according to requirements of clients. Offered furnace is highly demanded in industrial places for melting hard materials such as steel, iron and alloy. In addition to this, provided Melting Induction Furnace is checked on several parameters for ensuring flawless delivery of it.

Advanced Melting Technology for Foundries

Our Melting Induction Furnace leverages powerful induction heating and advanced digital control panels for precision and speed. With rapid melting cycles and robust automation options, it's suitable for a wide range of metals and alloys. The water-cooled system ensures stability across continuous operations, while its compact design enables flexible installation even in limited spaces.

Superior Safety and Environmental Compliance

Safety is paramount in our design, with built-in features like overload protection, emergency stops, and real-time insulation monitoring. The furnace's construction prioritizes low emissions and energy efficiency, helping your facility meet environmental regulations. Plus, the eco-friendly operation supports sustainable industrial practices without compromising performance.

FAQ's of Melting Induction Furnace:

Q: How does the induction furnace achieve rapid melting times?

A: The furnace utilizes high-frequency induction heating and high-quality copper coils, allowing it to efficiently and evenly heat metals. Depending on model and charge capacity, it can achieve melting times between 25 to 60 minutes, thanks to its fast energy transfer and optimized control systems.Q: What metals and crucible types can the furnace process?

A: This induction furnace is compatible with a range of metals commonly used in foundries and metal casting industries. It supports magnesium, graphite, or silicon carbide crucibles, making it versatile for different melting applications and alloys.Q: When should I choose semi-automatic versus fully automatic operation?

A: Semi-automatic furnaces are ideal for operations where hands-on control is preferred or batch sizes are smaller. Fully automatic models are recommended for larger facilities seeking higher throughput and reduced manual intervention for increased productivity and consistency.Q: Where can the furnace be installed, and is on-site support provided?

A: Installation is flexible, with customizable dimensions to fit various industrial layouts. On-site support is available to ensure proper setup, commissioning, and operator training at your facility.Q: What is the process for controlling temperature and monitoring safety?

A: An advanced microprocessor or digital controller continuously monitors and regulates the melting temperature and furnace conditions. Safety systems include overload protection, emergency stop buttons, and insulation monitoring to ensure safe and reliable operation.Q: How energy efficient and eco-friendly is this induction furnace?

A: Designed for high efficiency, the furnace minimizes energy consumption and uses electric power as a clean fuel source. Its eco-friendly operation ensures low emissions, helping to fulfill environmental compliance requirements for industrial plants.Q: What are the key benefits of using this melting induction furnace in foundry and industrial applications?

A: Major advantages include rapid melting cycles, energy efficiency, customizable size and capacity, robust safety features, and a design that meets strict environmental standards-providing reliable, safe, and cost-effective metal processing for various industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Melting Spare Parts Category

Electromagnetic Components

Minimum Order Quantity : 10 Pieces

Size : Standard

Application : Electrical Assemblies, Automation, Control Panels

Feature : Durable, High Efficiency, Low Maintenance

Inductotherm Melting Furnace Spares

Minimum Order Quantity : 10 Pieces

Size : Standard/Custom

Application : Induction Melting Furnace

Feature : Corrosion Resistant, Accurate Fit, Durable

Frp Insulation Material

Minimum Order Quantity : 10 Pieces

Size : Customizable

Application : Electrical Insulation, Construction, Panels, Cable Tray

Feature : High Strength, Excellent Electrical Insulation, Corrosion Resistant, Lightweight

Aluminium Plate Casting

Minimum Order Quantity : 10 Pieces

Size : Customizable as per requirement

Application : Used in heavy engineering, manufacturing, and construction

Feature : Corrosion Resistant, High Strength, Durable

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free