Aluminium Plate Casting

Aluminium Plate Casting Specification

- Rating

- ISO 9001 Certified

- Feature

- Corrosion Resistant, High Strength, Durable

- Condition

- New

- Type

- Industrial Plate Casting

- Usage

- For Machinery and Structural Applications

- Size

- Customizable as per requirement

- Dimensions

- Standard and Custom Sizes

- Weight

- Varies as per dimensions

- Application

- Used in heavy engineering, manufacturing, and construction

- Capacity

- Depends on size and specification

- Manufacturing Technique

- Sand Casting / Gravity Die Casting

- MOQ

- As per order

- Material Grade

- LM6/LM25 or as required

- Surface Finish

- Smooth, Shot Blasted

- Shape

- Rectangular / Custom

- Color

- Silver/Gray

- Packaging Type

- Wooden Box or As Per Client Requirement

- Hardness

- Up to 70 BHN

- Tolerance

- ±0.05 mm

- Heat Treatment

- Available on request

Aluminium Plate Casting Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

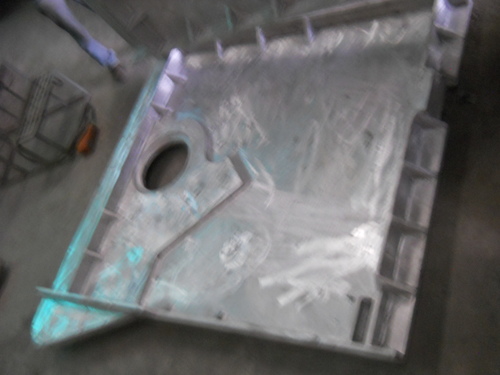

About Aluminium Plate Casting

We are a famous firm in this domain, engrossed in manufacturing and supplying optimum grade Aluminium Plate Casting. This plate is well appreciated among clients due to its sturdy construction, less maintenance, high strength and rust resistant surface. Offered plate is manufactured using top notch quality components by our adept professionals with cutting edge techniques. Offered plate is installed in furnace for providing support and strength to it. Provided plate is tested on different quality parameters before dispatching into market to ensure flawless delivery of it to clients. In addition to this, offered Aluminium Plate Casting is safely packed for avoiding damage during transit.

Aluminium Plate Casting

We are manufacturing stanchion assembly with Rugged HRS fabricated structure having base plate with proper isolated foundation arrangement.

All stanchions are analyzed for load carrying capacity of furnace with molten metal charge even while tilting of induction furnace.

Bearing and pivot assembly of highly finished grade of SS is fitted with this structure to tilt the furnace with molten bath.

Precision Engineering for Industrial Needs

Our aluminium plate castings deliver reliability and precision with customizable dimensions and stringent tolerances. Whether your application requires standard sizes or uniquely shaped solutions, we ensure the plates meet rigorous industry demands. Each piece undergoes strict quality checks, supporting heavy engineering, construction, and manufacturing sectors with consistent performance.

Advanced Casting Techniques

Utilizing sand casting and gravity die casting, we produce high-strength plates with a consistent surface finish. Our processes allow for the creation of both standard and tailored shapes, with heat treatment options available to further optimize mechanical properties. The combination of material expertise and manufacturing technology guarantees exceptional performance and robust longevity.

Quality Assurance and Customization

We are ISO 9001 certified, reflecting our commitment to quality and customer satisfaction. Aluminium plate castings are available in a range of colors, hardness levels up to 70 BHN, and can be boxed for safe delivery. Whether your requirement is for small or bulk orders, our flexible production capacity ensures timely fulfillment and tailored solutions.

FAQ's of Aluminium Plate Casting:

Q: How is the aluminium plate casting manufactured?

A: Aluminium plate castings are produced using sand casting or gravity die casting, depending on the required specifications. These techniques ensure the plates achieve a smooth, shot-blasted finish, precise dimensions, and optimal mechanical properties.Q: What material grades are used for aluminium plate castings?

A: We primarily use LM6 and LM25 aluminium alloys, recognized for their durability, high strength, and excellent corrosion resistance-making them suitable for heavy engineering and manufacturing applications.Q: When should heat treatment be requested for these castings?

A: Heat treatment can be requested when you require enhanced mechanical properties, such as improved hardness or increased strength, for specific application needs. Our team will customize the treatment to your requirements.Q: Where can aluminium plate castings be applied?

A: These castings are ideal for machinery, structural, construction, and heavy engineering sectors. Their robust material properties make them suitable for both industrial and infrastructural projects.Q: What is the minimum order quantity (MOQ) for aluminium plate castings?

A: The minimum order quantity is flexible and determined according to your project's requirements. We accommodate both small and large volume requests to ensure you receive exactly what you need.Q: How does the product packaging ensure safe delivery?

A: Aluminium plate castings are packed in sturdy wooden boxes or packaging as per client instructions to guarantee protection from damage during transit, ensuring the products arrive in pristine condition.Q: What are the benefits of using these aluminium plate castings?

A: These castings offer high corrosion resistance, durability, and strength. Their customizable features, precise tolerances, and superior surface finish make them ideal for various demanding industrial and structural applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Melting Spare Parts Category

Electromagnetic Components

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial

Application : Electrical Assemblies, Automation, Control Panels

Type : Electromagnetic Component

Feature : Durable, High Efficiency, Low Maintenance

Melting Induction Furnace

Minimum Order Quantity : 10 Pieces

Usage : Other, Metal Melting

Application : Foundry, Metal Casting, Industrial Melting Operations

Type : Industrial Melting Induction Furnace

Feature : Energy Efficient, Fast Melting, Compact Design, Advanced Temperature Control

Current Limiting Reactor

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial, Electrical Distribution

Application : Power Distribution, ShortCircuit Current Limiting

Type : Current Limiting Reactor

Feature : High Durability, Low Power Loss, Robust Design

Inductotherm Melting Furnace Spares

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial

Application : Induction Melting Furnace

Type : Induction Furnace Spare Part

Feature : Corrosion Resistant, Accurate Fit, Durable

Send Inquiry

Send Inquiry