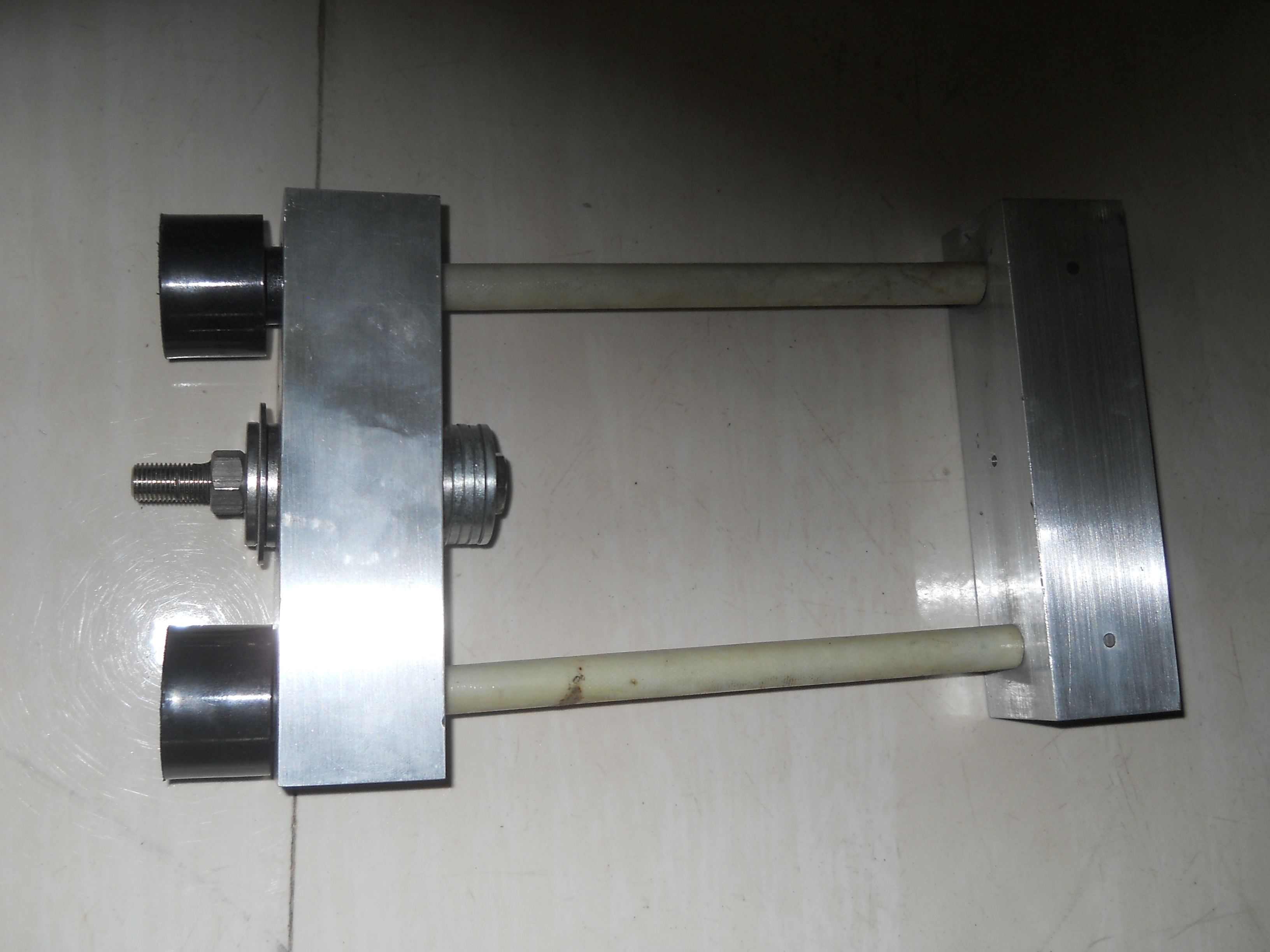

THYRISTORS and CLAMP ASSEMBLY

THYRISTORS and CLAMP ASSEMBLY Specification

- Rating

- 600V / 1200A

- Feature

- High Durability, Reliable Clamping

- Condition

- New

- Type

- Thyristor Clamp Assembly

- Usage

- Industrial

- Power

- High Power

- Voltage

- 600V

- Size

- Standard

- Dimensions

- Customized

- Weight

- 4-10 kg (Depending on Assembly)

- Application

- Power Electronics, Rectifier Circuits, Industrial Drives

- Fuel Type

- Electric

- Capacity

- High Current Handling

- Material

- Copper & Stainless Steel Clamp

- Temperature Range

- -40°C to +125°C

- Assembly Includes

- Insulation Plates, Clamping Bolts, Pressure Pads

- Compatible Devices

- Power Rectifiers, Inverters, Drives

- Element Type

- Disc Type Thyristor

- Finishing

- Anti-corrosion Coating

- Clamping Force

- Suitable for Secure Semiconductor Mounting

- Connection Type

- Bolt-Type Mounting

- Surface Treatment

- Galvanized

- Standards

- IEC Compliant

THYRISTORS and CLAMP ASSEMBLY Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About THYRISTORS and CLAMP ASSEMBLY

Backed with rich industrial experience, we have been engaged in manufacturing and supplying premium grade Thyristors & Clamp Assembly. Offered assembly is used for clamping and joining components in industrial applications. Provided assembly is known for its optimum strength, user-friendly design, longer life and robust construction. This assembly is available in various specifications according to needs of clients. Offered assembly is highly cherished among clients due to its excellent functionality and rust resistant surface. At advanced production unit, provided Thyristors & Clamp Assembly is manufactured using quality approved components under observation of our experienced professionals.

Exceptional Durability and Protection

Crafted from copper and stainless steel with an anti-corrosion coating and galvanized surface, the clamp assembly delivers outstanding durability in demanding industrial environments. Its robust material selection ensures longevity and consistent performance even under harsh operating conditions.

Precision Mounting and Secure Connection

Featuring bolt-type mounting and standardized dimensions, the assembly provides a secure and reliable connection for disc-type thyristors. The clamping force is optimized for safe semiconductor mounting, minimizing mechanical stress and enhancing operational safety for power rectifiers and inverters.

Flexible Industrial Compatibility

Meeting IEC standards and designed for high-power usage, this assembly seamlessly integrates into power electronics, rectifier circuits, and industrial drives. Its adaptability and robust construction make it suitable for diverse applications requiring high-current, high-durability solutions.

FAQ's of THYRISTORS and CLAMP ASSEMBLY:

Q: How is the thyristor clamp assembly installed?

A: The assembly uses bolt-type mounting for secure installation. Simply align the clamp with the semiconductor, insert insulation plates, place pressure pads, and fasten using clamping bolts to achieve uniform pressure and stable contact.Q: What benefits does the anti-corrosion galvanizing provide?

A: The anti-corrosion coating and galvanized surface protect the assembly against moisture, chemicals, and oxidation, significantly extending service life and maintaining reliable performance in harsh industrial settings.Q: When should this thyristor and clamp assembly be used?

A: It is ideal for deployment in industrial settings requiring high current handling, such as power rectifiers, inverters, and industrial drives, especially where secure semiconductor mounting and circuit stability are critical.Q: Where can this product be applied?

A: This assembly is suitable for power electronics, rectifier circuits, inverters, and industrial drive systems. Its robust build and high electrical ratings make it perfect for demanding environments across multiple industries.Q: What is included in the assembly process?

A: Each clamp assembly comes complete with insulation plates, clamping bolts, and pressure pads. The assembly process ensures that the disc-type thyristor is securely mounted with optimum clamping force for safe and stable operation.Q: How does the design ensure safe and efficient operation?

A: By adhering to IEC standards and using high-quality materials like copper, stainless steel, and anti-corrosion protection, the assembly delivers reliable clamping, excellent thermal conductivity, and electrical integrity under high loads.Q: What are the key benefits of using this thyristor clamp assembly?

A: Users benefit from high durability, reliable clamping force, resistance to corrosion, and compatibility with standard and custom-sized power devices. These factors combine to ensure efficient power handling and long-term operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

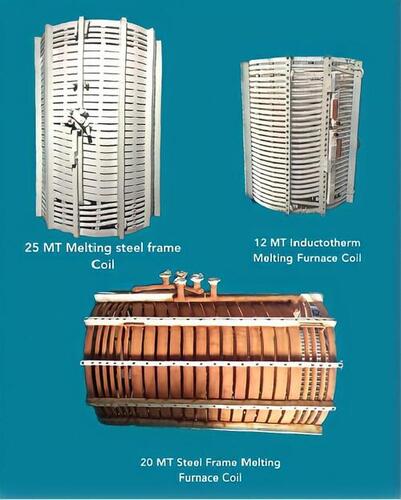

More Products in Induction Melting Furnace Spares Category

Induction Wire wound Resistors

Minimum Order Quantity : 10 Pieces

Feature : Low temperature coefficient, excellent stability, high reliability

Usage : Other, Industrial and Electrical Equipment

Condition : New

Application : Induction heating, Load banks, Motor control, Power supplies

Induction Coil Turns

Minimum Order Quantity : 10 Pieces

Feature : Corrosion Resistant, Durable Finish, Precision Designed

Usage : Other, Industrial Heating Applications

Condition : New

Application : Induction Heating, Melting, Hardening

Hydraulic Cylinders and Seal Kits

Minimum Order Quantity : 10 Pieces

Feature : High durability, corrosion resistant, robust construction, leak proof performance

Usage : Other, Industrial Machinery

Condition : New

Application : Heavy duty lifting, industrial equipment, construction machinery

HEAT EXCHANGER PLATES & GAS KIT

Minimum Order Quantity : 10 Pieces

Feature : Corrosionresistant, Easy to install, Compact design

Usage : Other, Industrial and Commercial

Condition : New

Application : Heat Transfer for HVAC, Food Processing, Chemical & Pharmaceutical Industries

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free