Induction Coil Turns

Induction Coil Turns Specification

- Feature

- Corrosion Resistant, Durable Finish, Precision Designed

- Rating

- High Efficiency

- Condition

- New

- Type

- Induction Coil

- Usage

- Industrial Heating Applications

- Power

- Customized

- Voltage

- 220-480V

- Size

- Variable as per requirement

- Dimensions

- Customized as per application

- Weight

- Varies as per size

- Application

- Induction Heating, Melting, Hardening

- Fuel Type

- Electric

- Capacity

- Application Specific

- Lead Type

- Flexible or Rigid Leads

- Material

- Copper/Enameled Copper

- Conductor Type

- Round or Square cross-section

- Mounting

- Clamp or Fixture Mountable

- Coil Shape

- Spiral, Rectangular, or Custom

- Operating Frequency

- Up to 500 kHz or as required

- Insulation Material

- Class F or H insulation

- Surface Finish

- High quality Insulation Coating

- Temperature Range

- -20°C to +200°C

Induction Coil Turns Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Induction Coil Turns

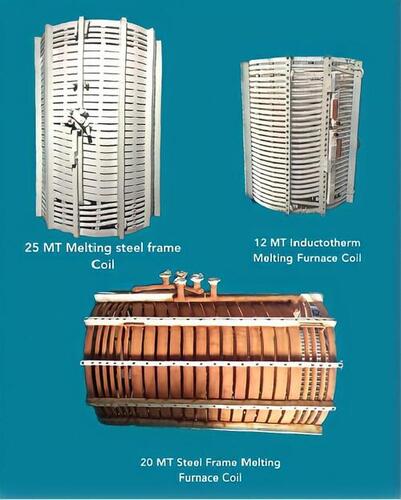

Having 8 years of industrial experience and knowledge, we have been engrossed in manufacturing and supplying quality approved Induction Coil Turns. Offered turns are manufactured using high grade components under guidance of our adept professionals with latest innovative techniques. Provided turns are installed in induction furnace to heat material up to desired temperature. These turns are available in several sizes according to needs of clients. Offered turns are safely packed for avoiding damage during transit. Provided turns are known for its excellent functionality, robustness and enhanced durability. In addition to this, offered Induction Coil Turns can be purchased from us at market leading prices.

Versatility in Shape and Size

Our induction coils come in a variety of shapes-spiral, rectangular, or fully customized-to precisely match your application's design parameters. Whether your operation requires specific dimensions or unique configurations, we accommodate with expert customization to ensure optimal performance and fit.

Engineered for High Efficiency and Durability

Constructed using premium copper or enameled copper conductors, these coils feature advanced insulation coatings and high-efficiency operation. Class F or H insulation and durable finishes ensure reliable performance in demanding industrial environments, resisting corrosion and sustaining efficiency over long periods.

FAQ's of Induction Coil Turns:

Q: How do you determine the suitable coil shape and material for my industrial heating application?

A: Our engineers assess your specific application-whether it's induction heating, melting, or hardening-to recommend the optimal coil shape (spiral, rectangular, or custom) and conductor type (copper or enameled copper). Key factors include space, frequency, heating profile, and power requirements.Q: What is the process for customizing an induction coil?

A: Customization begins with application analysis, followed by detailed discussions about frequency, size, power, and mounting requirements. Our design team then creates a specification and prototype for approval before manufacturing and assembling the final product as per your specifications.Q: When should I consider replacing my existing induction coil?

A: Replacement is recommended if performance declines due to overheating, insulation breakdown, or visible wear, especially when operating near maximum temperature or frequency ratings. Regular inspection helps extend coil lifespan and maintain efficiency.Q: Where can these induction coils be installed?

A: These coils are suitable for various industrial heating setups and can be easily integrated into new or existing systems. Mounting options include clamp or fixture mount, ensuring compatibility and secure installation in your facility.Q: What are the main benefits of choosing your induction coils for industrial applications?

A: Our induction coils offer high efficiency, precision engineering, and long-lasting durability. Enhanced insulation, corrosion resistance, and fully customized designs ensure reliable performance across a wide temperature and frequency range, meeting diverse industrial heating needs.Q: How do I ensure optimal usage and longevity of the coil?

A: Use within the recommended frequency, voltage, and temperature ranges; follow correct installation procedures; and conduct regular maintenance checks. This ensures the coil operates at peak efficiency and extends its service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Melting Furnace Spares Category

Pneumatic Valve

Minimum Order Quantity : 10 Pieces

Size : 1/4 inch to 1 inch

Usage : Other, Industrial Automation, Air Flow Control

Application : Compressed Air, Water, Neutral Gases

Condition : New

Hydraulic Cylinders and Seal Kits

Minimum Order Quantity : 10 Pieces

Size : Customized as per requirement

Usage : Other, Industrial Machinery

Application : Heavy duty lifting, industrial equipment, construction machinery

Condition : New

High Frequency Transformer

Minimum Order Quantity : 10 Pieces

Size : Standard / Customized

Usage : Other, Industrial / Electronic Device

Application : Switch Mode Power Supply, LED Driver, Charger, Power Electronics

Condition : New

Melting Furnace Spares

Minimum Order Quantity : 10 Pieces

Size : Customizable as per furnace model

Usage : Other, Replacement/maintenance in melting furnaces

Application : Melting Furnace

Condition : New

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free