Induction Wire wound Resistors

Induction Wire wound Resistors Specification

- Feature

- Low temperature coefficient, excellent stability, high reliability

- Rating

- Up to 50W or as specified

- Condition

- New

- Type

- Wire Wound Resistor

- Usage

- Industrial and Electrical Equipment

- Power

- 1W to 50W or tailored per requirement

- Voltage

- Up to 600V

- Size

- Standard and Custom sizes available

- Dimensions

- Varies by model, e.g., Length: 30-100mm; Diameter: 6-18mm

- Weight

- Varies as per size (approx. 20g 150g)

- Application

- Induction heating, Load banks, Motor control, Power supplies

- Fuel Type

- Not Applicable (Electrical Product)

- Capacity

- High surge and overload handling

- Insulation Resistance

- >1000 M at 500V DC

- Tolerance

- 1%, 2%, 5%, 10%

- Coating

- Silicone or vitreous enamel coated

- Body Material

- Ceramic core

- Packaging Type

- Bulk Packed or as required

- Resistance Range

- 0.1 Ohm to 10 Kilo Ohm

- Temperature Range

- -55C to +200C

- Compliance

- RoHS & CE Certified

- Mounting type

- Axial or Radial leads

- Lead Material

- Tinned copper

- Max Pulse Load

- High, designed for induction and heavy duty cycles

Induction Wire wound Resistors Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- ahmedabad

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Induction Wire wound Resistors

We have developed competitive edge over other market players, by manufacturing and supplying a wide range of Wirewound Resistors. It is an electrical passive component that limits current. Our expert workforce manufactures these resistors using finest quality materials, procured from the most reliable and trusted vendors. We can make the Wirewound Resistors available for the clients in different sizes and power specifications as per the requirements. Also, we offer our products at reasonable prices.

Features:

-

Light in weight

-

Shock proof

-

Durable quality

Precision Performance and High Reliability

Engineered for excellence, these wire wound resistors deliver low temperature coefficients and remarkable stability under heavy duty cycles. The ceramic core construction and quality coating ensure high durability, even during frequent surges and overloads-making them a preferred choice in industrial environments.

Versatile Mounting and Customization

Flexible mounting options with both axial and radial leads cater to diverse installation needs. Standard and tailored sizes, ratings, and packaging options support seamless integration into existing and new designs, providing a robust solution for manufacturers, suppliers, and system integrators alike.

Certified for Safety and Sustainability

RoHS and CE certifications confirm these resistors meet global safety, environmental, and performance standards. Their high insulation resistance and sturdy construction ensure long-term reliability and safe operation in critical electrical and industrial systems.

FAQ's of Induction Wire wound Resistors:

Q: How are these induction wire wound resistors typically used in industrial and electrical equipment?

A: These resistors are commonly utilized in induction heating systems, load banks, motor control circuits, and power supplies due to their high pulse load endurance and ability to maintain stable resistance under demanding conditions.Q: What benefits do the ceramic core and silicone/vitreous enamel coating offer?

A: The ceramic core provides high thermal stability and efficient heat dissipation, while the silicone or vitreous enamel coating protects against environmental factors, ensuring improved reliability and extended service life-even in harsh operating environments.Q: Where can these resistors be mounted, and are custom sizes available?

A: The resistors support both axial and radial lead mounting, making them adaptable to various installation configurations. Standard sizes are available, and custom dimensions and ratings can be manufactured to meet specific application requirements.Q: What is the process for selecting the correct resistor for my application?

A: Determine your application's voltage, power, and resistance needs, then select a resistor within the offered range (1W-50W, 0.1 Ohm-10 Kilo Ohm). Ensure the chosen tolerance, temperature range, and mounting type match your operational specifications. Custom engineering is available for unique requirements.Q: When should I choose a resistor with a particular tolerance level (1% to 10%)?

A: Select tighter tolerance (1% or 2%) when precise resistance is critical for circuit performance. Use higher tolerance (5% or 10%) where slight variations are acceptable, often in less sensitive or cost-driven applications.Q: What ensures the safety and longevity of these resistors?

A: Their insulation resistance exceeding 1000 M at 500V DC, compliance with RoHS and CE standards, robust core and coating materials, and tested performance across wide temperature ranges ensure both safe operation and extended lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

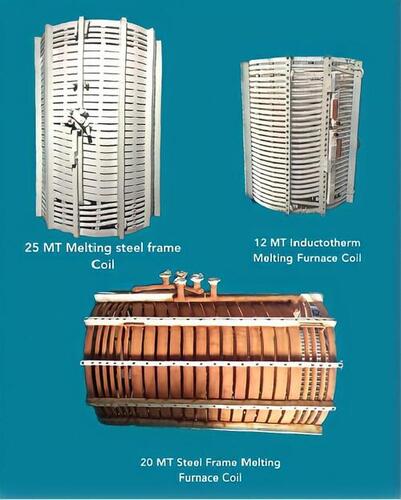

More Products in Induction Melting Furnace Spares Category

Induction Coil Turns

Minimum Order Quantity : 10 Pieces

Size : Variable as per requirement

Feature : Corrosion Resistant, Durable Finish, Precision Designed

Usage : Other, Industrial Heating Applications

Application : Induction Heating, Melting, Hardening

HEAT EXCHANGER PLATES & GAS KIT

Minimum Order Quantity : 10 Pieces

Size : Customizable as per requirement

Feature : Corrosionresistant, Easy to install, Compact design

Usage : Other, Industrial and Commercial

Application : Heat Transfer for HVAC, Food Processing, Chemical & Pharmaceutical Industries

Snubber Diodes and Capacitors

Minimum Order Quantity : 10 Pieces

Size : Standard, Custom Sizes Available

Feature : Overvoltage Protection, Low Loss, Robust Design

Usage : Other, Used for Protection in Electrical Circuits

Application : Industrial, Electronics, Power Supply Protection, Inverters

High Frequency Transformer

Minimum Order Quantity : 10 Pieces

Size : Standard / Customized

Feature : High efficiency, low losses, compact design, lightweight

Usage : Other, Industrial / Electronic Device

Application : Switch Mode Power Supply, LED Driver, Charger, Power Electronics

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free