Magnetic Yoke

Magnetic Yoke Specification

- Feature

- Lightweight, Durable, Portable, High Sensitivity

- Rating

- 230V, 4.5A

- Condition

- New

- Type

- Electromagnetic Yoke

- Usage

- Industrial NDT Testing, Crack Detection

- Power

- AC Powered

- Voltage

- 220-240V AC

- Size

- Standard

- Dimensions

- Approx. 220 mm (L) x 185 mm (H) x 60 mm (W)

- Weight

- Approx. 3 kg

- Application

- Magnetic Particle Inspection (MPI)

- Fuel Type

- Electric

- Capacity

- Can Lift Up To 23 Kg

- Cable Length

- 2 meters

- Operating Temperature

- -10C to +50C

- Frequency

- 50/60 Hz

- Arm Span

- 85 mm 255 mm Adjustable

- Control Switch

- Handheld On/Off Switch

- Inspection Surface Type

- Flat and Curved Surfaces

- Safety Standard

- Complies with IS 10993, ASTM E1444/E709

- Enclosure Material

- Heavy Duty Plastic/Aluminum Alloy

Magnetic Yoke Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Magnetic Yoke

Supported by a group of highly qualified & experienced engineers, we are engaged in manufacturing and supplying an exclusive range of Magnetic Yoke. These are used to detect fatigue cracks in metal surfaces. We manufacture the yoke, using high quality materials, procured from the most reliable and trusted vendors. Our Magnetic Yoke is available in different models and specifications as per the client's requirements. Moreover, we offer the products at the reasonable prices.

Features:

-

Easy to use

-

Sturdy design

-

Durable quality

High-Performance and Adjustable Design

The magnetic yoke features an adjustable arm span of 85 mm to 255 mm, allowing users to inspect various sizes and shapes, from flat to curved surfaces. The robust construction guarantees long-term durability in demanding industrial environments. This versatility and resilient build make it ideal for a host of magnetic particle inspection tasks.

Lightweight and User-Friendly Operation

Weighing approximately 3 kg with a portable build, this yoke facilitates easy handling and transportation. The ergonomic hand-held on/off switch allows users complete control during inspections, ensuring precise and efficient operation every time.

Certified Safety and Industry Compliance

Engineered to comply with IS 10993 and ASTM E1444/E709 standards, this magnetic yoke guarantees safety and efficacy in non-destructive testing. It is a trusted choice for exporters, manufacturers, suppliers, and traders across India, serving critical industrial inspection needs.

FAQ's of Magnetic Yoke:

Q: How is the magnetic yoke used for industrial NDT and crack detection?

A: This magnetic yoke is placed on the surface being tested, generating a magnetic field when powered on using the hand-held switch. Magnetic particles are applied, and any surface or near-surface discontinuity, like cracks, can be identified by particle accumulation. It is suitable for both flat and curved surfaces.Q: What surfaces can I inspect with this magnetic yoke?

A: The yoke is designed for versatility, enabling inspection of both flat and curved surfaces. Its adjustable arm span (85 mm to 255 mm) lets users adapt to various component shapes and sizes in industrial settings.Q: When should I use this magnetic yoke in my inspection process?

A: Use this magnetic yoke during routine or critical inspections where non-destructive magnetic particle testing is required, especially for detecting surface and near-surface cracks in ferromagnetic materials.Q: Where is this magnetic yoke commonly applied?

A: It is widely used in industrial sectors across India for Magnetic Particle Inspection (MPI), including manufacturing, fabrication, maintenance, and quality control of metal components.Q: What are the key benefits of using this adjustable magnetic yoke?

A: The yoke provides high sensitivity for crack detection, compliant safety standards (IS 10993, ASTM E1444/E709), portability, lightweight structure (~3 kg), and durable construction. Its adjustable design enhances flexibility across varied inspection scenarios.Q: How does the control switch and cable length improve the inspection process?

A: The hand-held on/off switch gives users direct operational control for efficient testing, while the 2-meter cable offers ample mobility and reach during inspections, boosting overall usability.Q: What makes this magnetic yoke compliant and safe for industrial use?

A: It adheres to recognized safety and testing standards (IS 10993, ASTM E1444/E709), uses durable materials for its enclosure, and is rated for 230V, 4.5A operation, ensuring reliable and safe industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

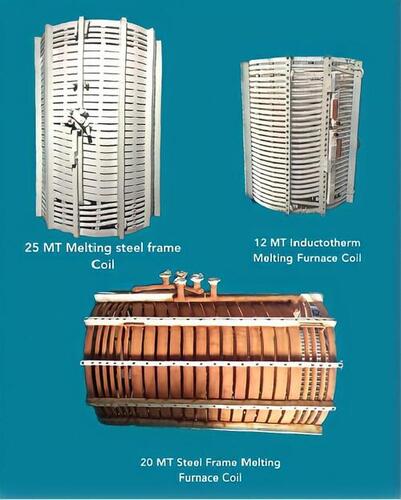

More Products in Induction Melting Furnace Spares Category

Water Cooled Cables

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial Suitable for welding, induction furnace, and foundry applications

Size : Flexible, available in multiple crosssectional areas (25 mm to 3000 mm)

Application : Steel Plants, Foundries, Arc Furnaces, Welding Equipment

Feature : Highly flexible, anticorrosive, water cooled for continuous duty

Induction Coil Turns

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial Heating Applications

Size : Variable as per requirement

Application : Induction Heating, Melting, Hardening

Feature : Corrosion Resistant, Durable Finish, Precision Designed

Pneumatic Valve

Minimum Order Quantity : 10 Pieces

Usage : Other, Industrial Automation, Air Flow Control

Size : 1/4 inch to 1 inch

Application : Compressed Air, Water, Neutral Gases

Feature : Corrosion Resistant, Quick Response

Snubber Diodes and Capacitors

Minimum Order Quantity : 10 Pieces

Usage : Other, Used for Protection in Electrical Circuits

Size : Standard, Custom Sizes Available

Application : Industrial, Electronics, Power Supply Protection, Inverters

Feature : Overvoltage Protection, Low Loss, Robust Design

Send Inquiry

Send Inquiry