Furnace Assembly Coil

Furnace Assembly Coil Specification

- Rating

- Industrial Grade

- Feature

- High thermal efficiency, corrosion resistance, quick heating

- Condition

- New

- Type

- Furnace Assembly Coil

- Usage

- Heating element in furnaces

- Power

- 3 kW to 50 kW (custom range available)

- Voltage

- 220 V / 380 V / 415 V

- Size

- Customizable as per requirement

- Dimensions

- As per application specification

- Weight

- Depends on size and configuration

- Application

- Industrial furnaces, heat treatment, melting

- Fuel Type

- Electric

- Capacity

- Up to 2000C operating temperature

- Lead Terminals

- Copper or nickel plated terminals

- Maximum Surface Load

- 6-10 W/cm²

- Shape

- Spiral/Helical/Customized

- Insulation

- High temperature ceramic/ refractory insulation

- Material

- High grade resistance alloy (e.g., Kanthal, Nichrome)

- Surface Treatment

- Anti-oxidation coating

- Tolerance

- ±3% on resistance

- Mounting

- Bolt-on/Clamp type

- Testing

- 100% electrically and mechanically tested

Furnace Assembly Coil Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

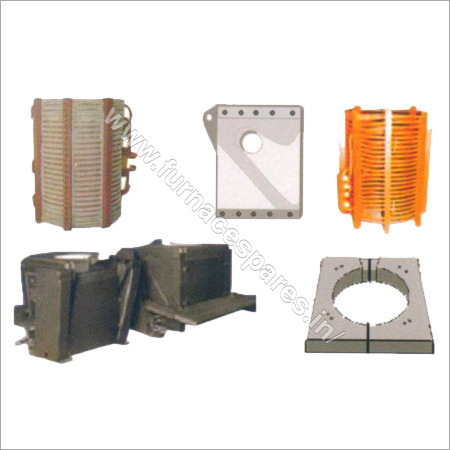

About Furnace Assembly Coil

We are aimed at maintaining high standards in this domain by manufacturing and supplying an extensive range of Furnace Assembly Coil. These coils are used in metallurgical industry for melting and heating metals. We use optimum quality materials, sourced from the trusted vendors to manufacture the coils. The coils are available in different power capacities as per the client's requirements. We offer our Furnace Assembly Coil at the pocket friendly prices.

Features:

-

Rugged construction

-

Longer service life

-

Easy installation

Customizable for Every Industrial Heating Need

Our furnace assembly coils offer complete customization in terms of shape, size, power rating, and mounting options. Whether you require spiraled, helical, or uniquely designed coils, we manufacture to your exact furnace specifications. This flexibility makes them ideal for various industrial uses, from heat treatment to metal melting.

Superior Materials and Advanced Insulation

Crafted with Kanthal, Nichrome, and similar high-resistance alloys, our coils ensure extended lifespan and consistent performance. The high-temperature ceramic or refractory insulation further enhances durability and prevents heat loss, boosting overall efficiency in rigorous industrial environments.

Rigorous Testing and Unmatched Reliability

Every coil is 100% electrically and mechanically tested before delivery, guaranteeing operational safety and adherence to industrial standards. Featuring anti-oxidation coatings and high-quality lead terminals, our coils are designed for effortless integration and long-term reliability in demanding furnace applications.

FAQ's of Furnace Assembly Coil:

Q: How is the furnace assembly coil installed in industrial furnaces?

A: The coil features bolt-on or clamp-type mounting options, allowing for secure and straightforward installation in a variety of furnace designs. The mounting approach can be customized according to your application's requirements.Q: What materials are used in the construction of these furnace coils?

A: Our coils are manufactured using high-grade resistance alloys such as Kanthal or Nichrome, combined with high-temperature ceramic or refractory insulation and copper or nickel-plated terminal leads for exceptional performance and durability.Q: When should I replace the furnace assembly coil in my industrial setup?

A: Replacement is recommended when you notice decreased heating efficiency, visible damage, or if resistance values drift beyond the prescribed 3% tolerance. Routine inspections can help in determining the coil's service condition.Q: Where are your furnace assembly coils commonly used?

A: These coils are widely used in industrial furnaces for applications such as heat treatment, metal melting, and high-temperature processing, particularly in settings requiring precise and consistent heating performance.Q: What is the process for customizing a furnace assembly coil?

A: You can provide your desired shape, size, power rating, voltage, and mounting preferences. Our engineering team will assist you throughout the customization process, ensuring your coil meets the exact specifications of your industrial furnace.Q: How do your coils benefit industrial heating operations?

A: Our coils deliver high thermal efficiency, rapid heating, and superior corrosion resistance. With customizable designs and robust construction, they help minimize downtime, improve process control, and extend equipment life in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Furnace Spare Parts Category

Furnace Parts

Minimum Order Quantity : 10 Pieces

Application : Heat Treatment Plant, Foundries, Smelting

Size : Customizable as per requirement

Feature : Corrosion Resistant, High Temperature Endurance, Durable

Usage : Other, Industrial Furnace

Furnace Spare Parts

Minimum Order Quantity : 10 Pieces

Application : Replacement and Repair of Furnace Systems

Size : Standard, Custom Available

Feature : Corrosion Resistant, High Durability

Usage : Other, Industrial Furnace Maintenance

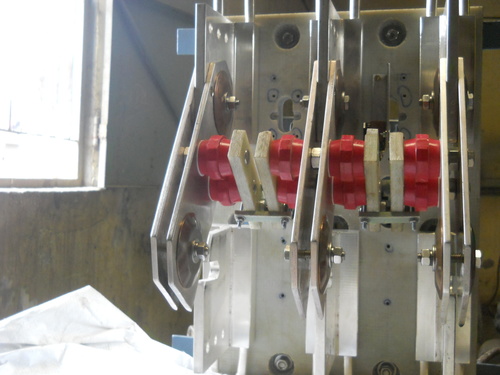

Furnace Selector Switch

Minimum Order Quantity : 10 Pieces

Application : Electric Furnaces, Ovens, Heaters

Size : Standard (Fits most panel mountings)

Feature : Highly Durable, Flameproof, Reliable Switching

Usage : Other, Furnace, Industrial Applications

Furnace Selector Switches

Minimum Order Quantity : 10 Pieces

Application : Furnace and Oven Power Switching

Size : Standard (customizable on request)

Feature : High Durability, Heat Resistant, Easy to Fit, Sturdy Construction

Usage : Other, Industrial Furnace Control

Send Inquiry

Send Inquiry