Furnace Parts

Furnace Parts Specification

- Glass Size

- Applicable as per requirement (if provided)

- Feature

- Corrosion Resistant, High Temperature Endurance, Durable

- Rating

- Industrial Grade

- Condition

- New

- Type

- Furnace Accessories

- Usage

- Industrial Furnace

- Power

- Electric / Gas Fired Compatible

- Voltage

- 220V/380V/440V (as required)

- Size

- Customizable as per requirement

- Dimensions

- Standard/Customized

- Weight

- As per part & specification

- Application

- Heat Treatment Plant, Foundries, Smelting

- Fuel Type

- Electric, Gas, Oil

- Capacity

- Depends on Furnace Spec

- Surface Finish

- Polished/Coated

- Material

- Stainless Steel, Alloy Steel, Refractory Materials

- Connection Type

- Flanged, Threaded, Welded

- Usage Life

- Long Life / Heavy Duty

- Custom Made

- Available as per Drawings / Samples

- Compatibility

- Fits Most Standard Furnaces

- Temperature Range

- Up to 1600°C

- Color

- Silver, Grey

Furnace Parts Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Furnace Parts

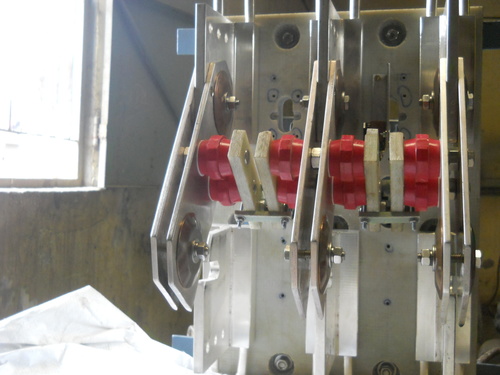

Set to ensure complete satisfaction to our customers, we are engaged in manufacturing and supplying a wide range of Furnace Parts. These parts are used to install in melting and heating furnaces of various metallurgical industries. The parts are manufactured by our dexterous manpower using superior grade materials, obtained from authentic vendors. Our Furnace Parts are available in different sizes and finishing as per the client's requirements.

Features:

-

Rugged construction

-

Rust proof finishing

-

Easy installation

Engineered for Heavy-Duty Performance

These furnace accessories are industrially rated and constructed to deliver exceptional durability and reliability. Designed to resist corrosion and endure extreme temperatures, they provide stable operation even in the most challenging applications, minimizing downtime and maintenance needs.

Custom Manufacturing for Specific Requirements

We offer furnace parts tailored to your exact specifications, using customer drawings or samples. Every component-whether requiring flanged, threaded, or welded connections-can be customized in size, weight, and dimension to fit the unique needs of various industrial furnaces.

Versatile Applications Across Industries

Our furnace parts are ideal for a wide range of high-temperature applications. They find use in heat treatment plants, smelting, and foundries, supporting processes involving electric, gas, and oil fuel sources. Their compatibility with both standard and specially designed furnaces ensures broad utility.

FAQ's of Furnace Parts:

Q: How are these furnace parts manufactured to withstand extreme temperatures?

A: Our furnace parts are crafted from durable stainless steel, alloy steel, and refractory materials, allowing them to endure temperatures up to 1600C. Special coatings and polished finishes further enhance their resistance to heat and thermal stress, ensuring longevity in industrial operations.Q: What connection types are available for installation?

A: We provide flanged, threaded, and welded connections to adapt to a wide array of furnace configurations. This flexibility ensures compatibility with most standard industrial furnaces, as well as custom-designed systems.Q: When should I consider upgrading to custom-made furnace parts?

A: You should opt for custom furnace parts if you have specialized requirements such as unique dimensions, connection interfaces, or if you are working with non-standard or legacy furnace models. Custom components are also preferred for optimized efficiency and seamless integration with existing setups.Q: Where can these furnace accessories be used?

A: Our furnace parts are suitable for use in heat treatment plants, foundries, smelting facilities, and any industrial environment requiring durable, high-temperature accessories. They function efficiently with both electric and gas-fired furnaces.Q: What is the process to order customized furnace parts?

A: You can provide us with your technical drawings or samples. Our engineering team will review your requirements, offer material and connection recommendations, and manufacture parts tailored to your application, ensuring they meet all quality and compatibility standards.Q: How do these furnace parts benefit industrial operations?

A: Designed for long-life and resistant to corrosion, our parts minimize wear and enhance operational reliability. Their compatibility with standard voltages (220V, 380V, 440V) and custom sizing options allow seamless integration, reducing the risk of downtime and increasing furnace efficiency.Q: What distinguishes the usage of these furnace parts in industrial settings?

A: These accessories are built for continuous use in intensive operations, offering high temperature endurance, structural stability, and the ability to function with various fuel types and voltages. Their robust construction makes them a preferred choice for industries seeking heavy-duty and reliable components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Furnace Spare Parts Category

Furnace Spare Parts

Minimum Order Quantity : 10 Pieces

Size : Standard, Custom Available

Usage : Other, Industrial Furnace Maintenance

Application : Replacement and Repair of Furnace Systems

Feature : Corrosion Resistant, High Durability

Furnace Selector Switches

Minimum Order Quantity : 10 Pieces

Size : Standard (customizable on request)

Usage : Other, Industrial Furnace Control

Application : Furnace and Oven Power Switching

Feature : High Durability, Heat Resistant, Easy to Fit, Sturdy Construction

Furnace Selector Switch

Minimum Order Quantity : 10 Pieces

Size : Standard (Fits most panel mountings)

Usage : Other, Furnace, Industrial Applications

Application : Electric Furnaces, Ovens, Heaters

Feature : Highly Durable, Flameproof, Reliable Switching

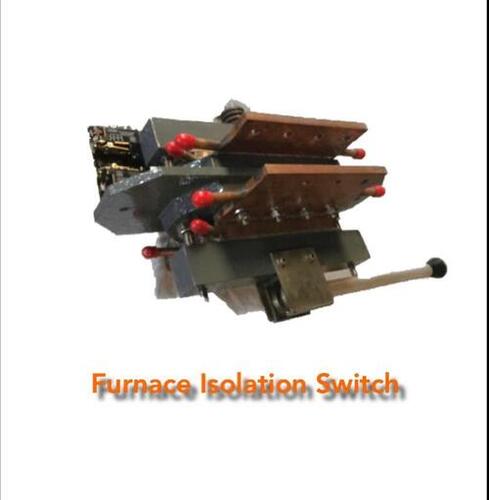

Furnace Isolation Switches

Minimum Order Quantity : 10 Pieces

Size : Standard/Customized

Usage : Other, Industrial / Furnace Isolation

Application : Furnace / Electrical Panel Isolation

Feature : High Durability, Fire Resistant, Shock Proof

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free