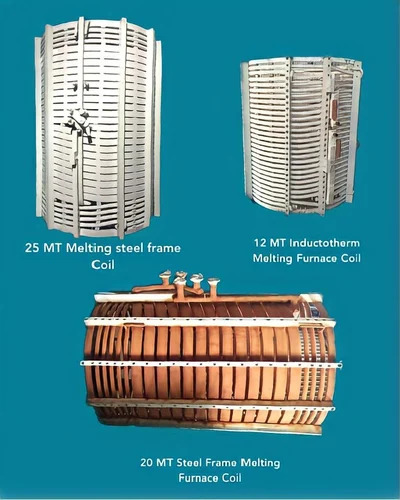

Induction Furnace Coils (20Ton-25Ton-30Ton Steel Frame)

Price 2100000 INR/ Unit

MOQ : 1 Unit

Induction Furnace Coils (20Ton-25Ton-30Ton Steel Frame) Specification

- Condition

- New

- Type

- Copper Winding

- Usage

- Steel Melting Furnace

- Size

- 20 Ton, 25 Ton, 30 Ton

- Application

- Steel Melting

- Capacity

- 20-30 Ton

- Material

- Mild Steel

- Frame Type

- Steel Frame

- Cooling

- Water Cooled

- Phase

- Three Phase

- Model Name/Number

- Inductotherm / Electrotherm

- Temperature

- 1500°C

- Spark Length

- Variable

- Customizable

- Customer Requirement

- Coil Material

- High Conductivity Copper

Induction Furnace Coils (20Ton-25Ton-30Ton Steel Frame) Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 7 Days

About Induction Furnace Coils (20Ton-25Ton-30Ton Steel Frame)

Unlock elite performance in steel melting with our Best-seller Induction Furnace Coils (20Ton-25Ton-30Ton Steel Frame), model Inductotherm/Electrotherm. Crafted from dominant mild steel frames and brilliant high conductivity copper windings, each coil operates at a formidable 1500C and supports three-phase power. The water-cooled system ensures efficient cooling, while variable spark length and customizable options meet every customer's requirement. Suitable for steel melting furnaces, this new, premium product guarantees elevated productivity and reliability for exporters, manufacturers, suppliers, and traders across India.

Advanced Application & Competitive Edge

These induction furnace coils are meticulously engineered for steel melting, ensuring robust application on various surfaces. With their steel frame construction and copper winding, they offer brilliant conductivity and heat endurance. Extra features like variable spark length and advanced water cooling provide dominant operational benefits over conventional coils, enhancing efficiency and minimizing downtime. Customization options allow seamless integration for specific melting requirements, giving customers a remarkable competitive edge in the metals industry.

Shipping, Samples & Premium Delivery

Shipped goods depart promptly via premium FOB ports across India, aligning with global standards. Our sample policy involves competitive asking price quotations, enabling buyers to assess quality before bulk orders. Experience swift delivery-standard coils are dispatched within 10-18 business days, ensuring your steel melting operations remain uninterrupted. Commitment to customer satisfaction is reinforced with secure packaging and reliable logistics, making us a preferred supplier for timely equipment arrival and expert service.

Advanced Application & Competitive Edge

These induction furnace coils are meticulously engineered for steel melting, ensuring robust application on various surfaces. With their steel frame construction and copper winding, they offer brilliant conductivity and heat endurance. Extra features like variable spark length and advanced water cooling provide dominant operational benefits over conventional coils, enhancing efficiency and minimizing downtime. Customization options allow seamless integration for specific melting requirements, giving customers a remarkable competitive edge in the metals industry.

Shipping, Samples & Premium Delivery

Shipped goods depart promptly via premium FOB ports across India, aligning with global standards. Our sample policy involves competitive asking price quotations, enabling buyers to assess quality before bulk orders. Experience swift delivery-standard coils are dispatched within 10-18 business days, ensuring your steel melting operations remain uninterrupted. Commitment to customer satisfaction is reinforced with secure packaging and reliable logistics, making us a preferred supplier for timely equipment arrival and expert service.

FAQ's of Induction Furnace Coils (20Ton-25Ton-30Ton Steel Frame):

Q: How do Induction Furnace Coils with steel frames enhance steel melting processes?

A: Induction Furnace Coils with steel frames ensure maximum strength and stability during high-temperature operation, promoting efficient heat transfer and uniform steel melting.Q: What materials are used in these coils and why are they chosen?

A: The coils use mild steel for the frame and high conductivity copper for windings. These materials are selected for their excellent mechanical durability and superior electrical performance in demanding environments.Q: When can customers expect delivery after placing an order?

A: Delivery times typically range from 10 to 18 business days, depending on the product specification and customization requirements.Q: Where are the coils shipped from and what are the export facilities available?

A: All coils are shipped from premium FOB ports across India, backed by advanced export facilities designed to handle bulk shipments efficiently.Q: What is the process for ordering samples of these coils?

A: Customers can request samples at competitive asking prices. Samples are provided promptly, enabling evaluation of product quality and suitability for specific melting applications.Q: How does water cooling in the coils benefit operational efficiency?

A: Water cooling maintains optimal coil temperature, reduces thermal stress, and prolongs coil lifespan, resulting in more consistent and reliable steel melting performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Induction Furnace Coil Category

Induction Furnace Parts - Control Card, Aci, Monitor

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Usage : Industrial

Size : Standard

Inductotherm Steel Frame Furnaces

Price 1300000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Usage : Industrial

Size : Standard

Melting Furnace Cradle

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Usage : Other, Melting Metal

Power : Electric

Induction Melting Furnace Spares - 8 Ton

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Usage : Other, Industrial

Power : Electric

Send Inquiry

Send Inquiry